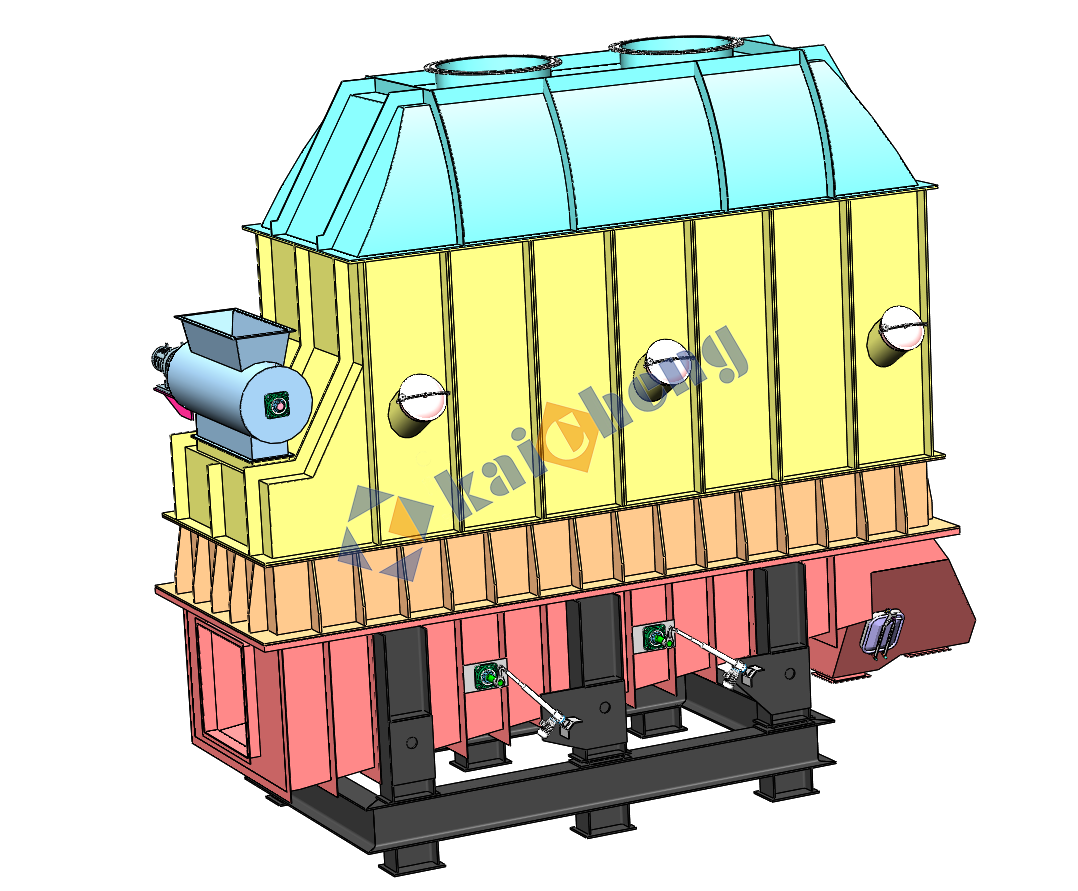

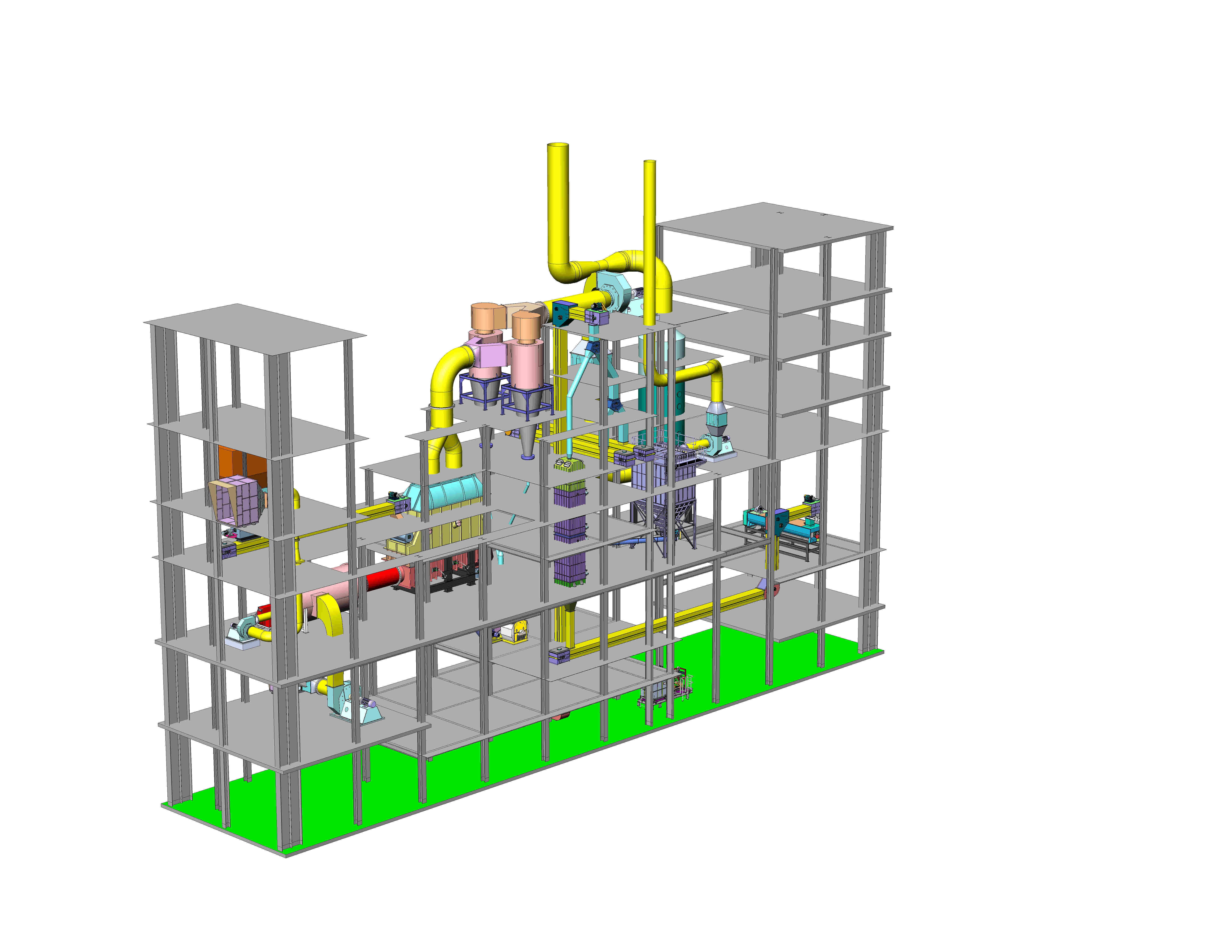

Static boiling fluidized bed dryer

1. Inorganic Salts: Wet cake drying of potassium chloride, sodium chloride, potassium sulfate, ammonium chloride, etc. 2. Chemical Raw Materials: Drying of granular materials such as sodium bicarbonate, sodium carbonate, and sodium citrate 3. Mineral Processing: Drying of wet materials such as phosphate rock powder, limestone powder, and fluorite powder 4. Food and Pharmaceuticals: Drying of low-viscosity materials such as starch, protein powder, and traditional Chinese medicine granules (material can be upgraded to food-grade 304/316L).

Product Attachments:

Keywords: Static boiling fluidized bed dryer

- Description

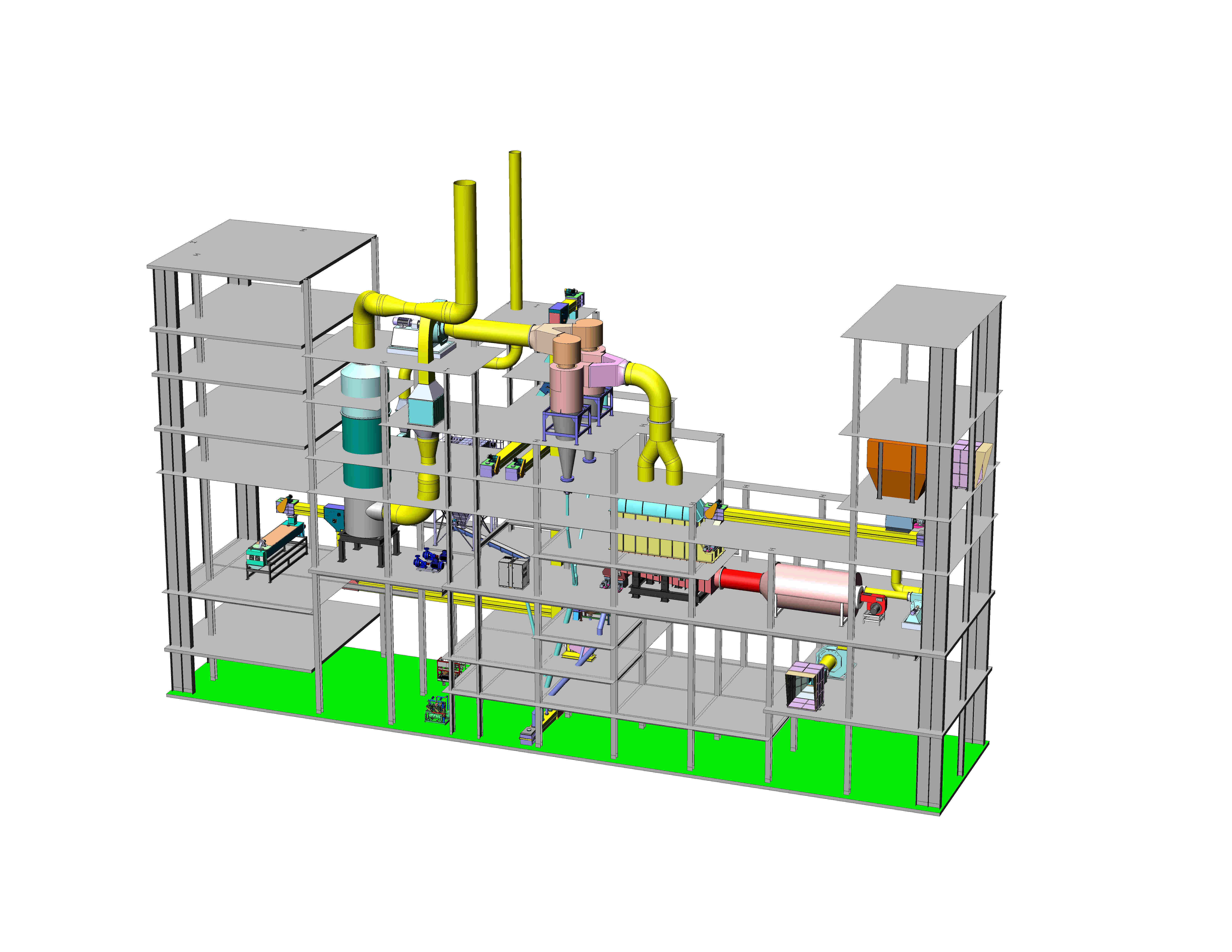

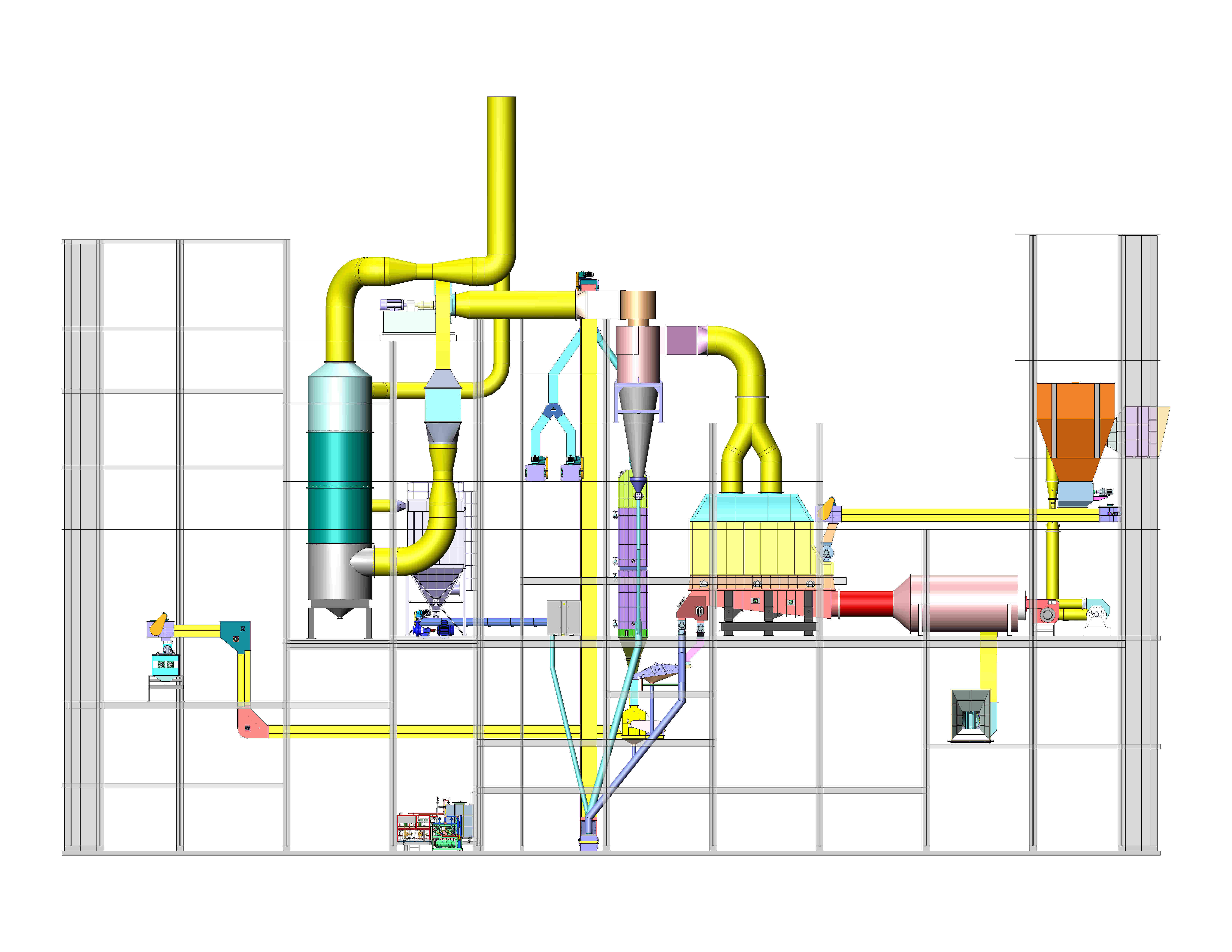

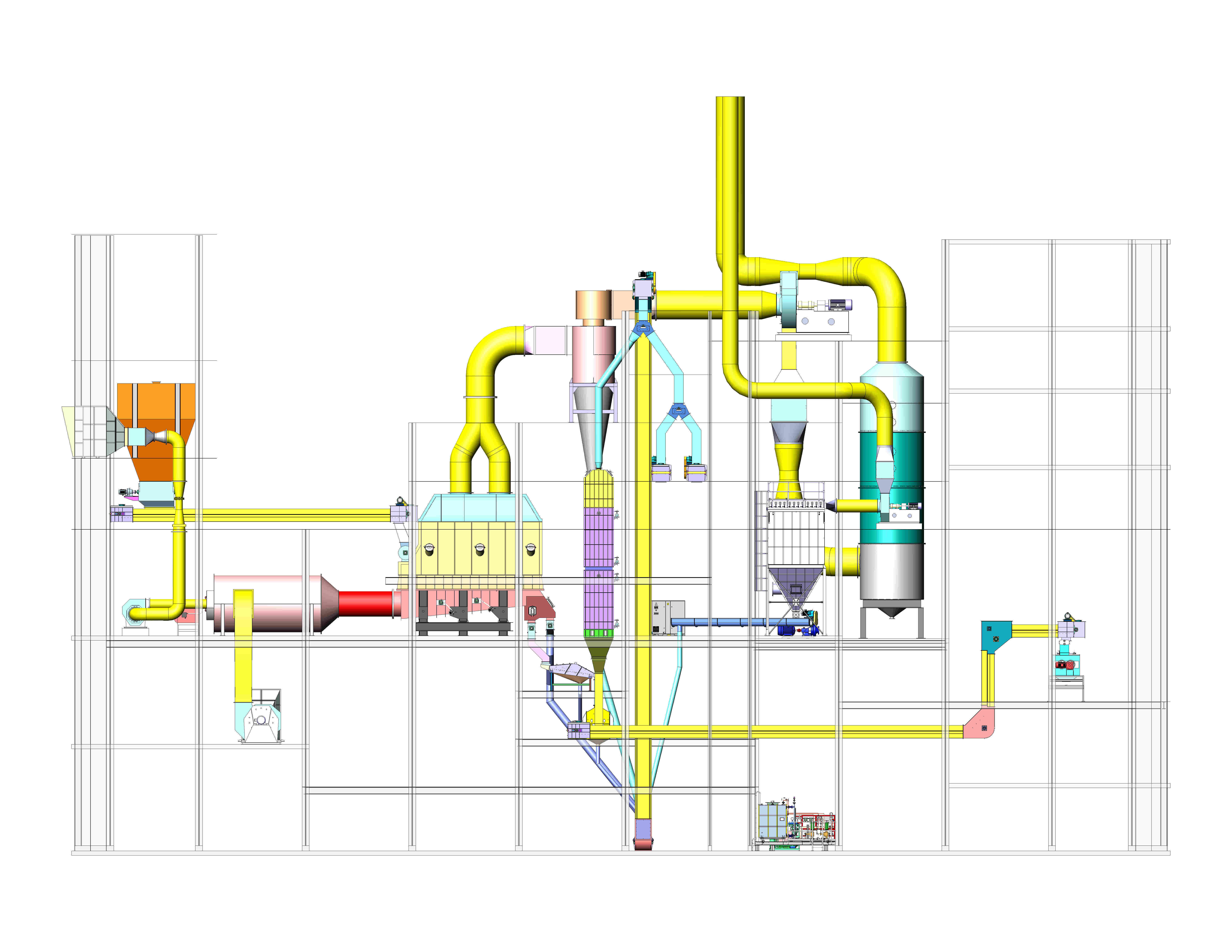

- Schematic Diagram

- Parameter

- Result

-

A. Core Technology Principles

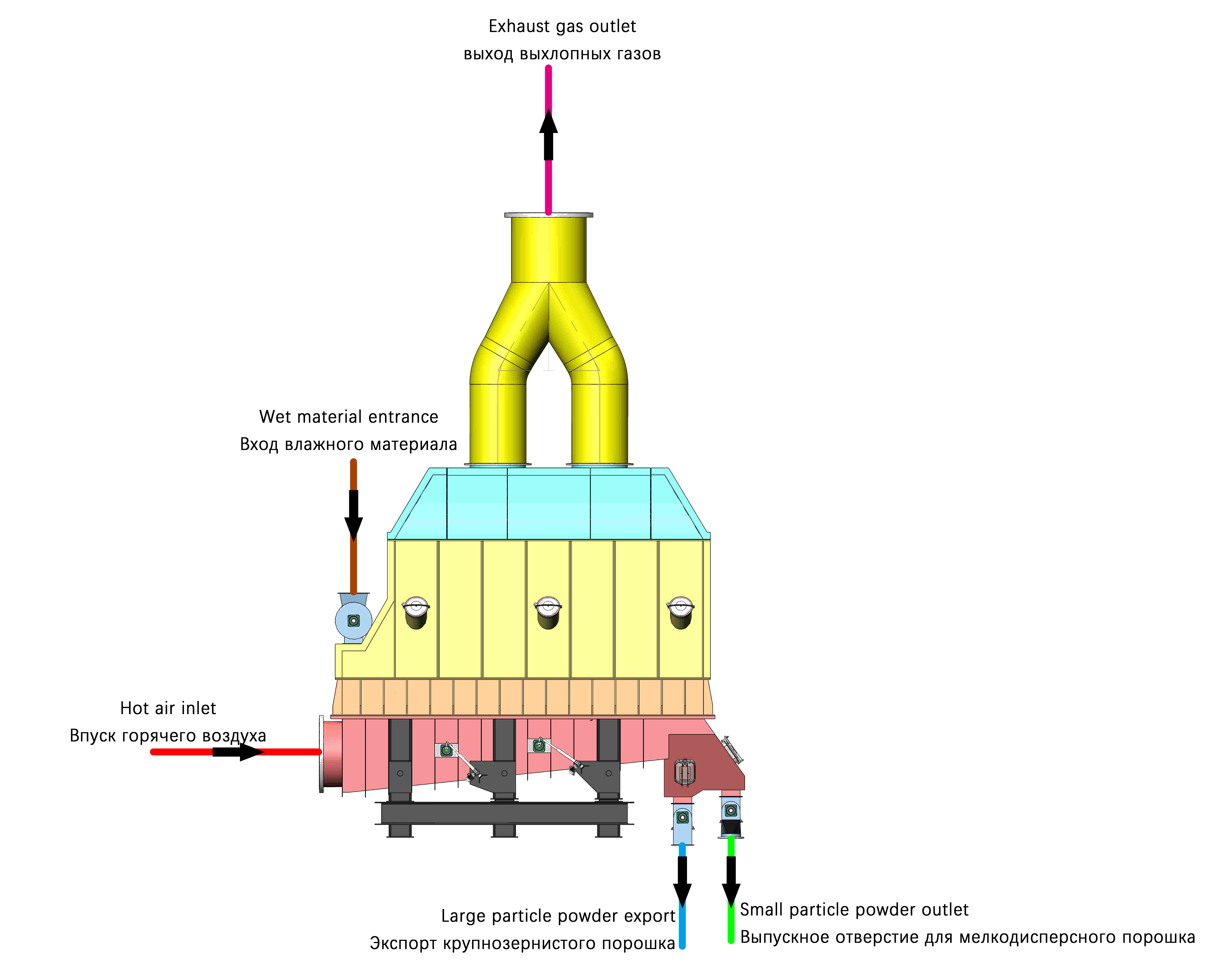

1. Material Spreading and Air Supply

1) The wet material is continuously and evenly spread across the porous distribution plate inside the dryer via a feeder.

2) Simultaneously, clean hot air generated by the hot air furnace is forced into the dryer from below the distribution plate by an induced draft fan.

2. Fluidization ("Boiling")

1) When hot air passes through the small holes in the distribution plate at a constant speed, a uniform airflow forms above the plate.

2) This airflow exerts an upward drag on the material particles. When this drag exceeds the particles' own weight, the material particles on the bed begin to suspend, and the friction between the particles disappears.

3) At this point, the entire material bed becomes fluid, like a boiling liquid. This state is known as the "fluidized" or "boiling" state.

3. Efficient Heat and Mass Transfer

1) In the fluidized state, each material particle is completely enveloped by the hot air, maximizing the gas-solid contact area. 2) Heat Transfer: The heat from the hot air is quickly and evenly transferred to each material particle.

3) Mass Transfer: Moisture within the material is rapidly heated and vaporized, then diffused onto the particle surface and carried away by the hot air flow.

4) This direct, large-area contact makes the drying process extremely fast and efficient.

4. Classification and Discharge

1) The dried material moves forward on the bed. By adjusting the bed's inclination or the height of the outlet weir, the material's residence time within the bed can be controlled to ensure the moisture content meets the specified standard.

2) The dried product is discharged from the discharge port and enters the next process step (such as cooling or screening).

3) Fine dust particles are entrained in the airflow and discharged from the top of the dryer as exhaust gas, entering the subsequent dust removal system.B. Key Component Functions:

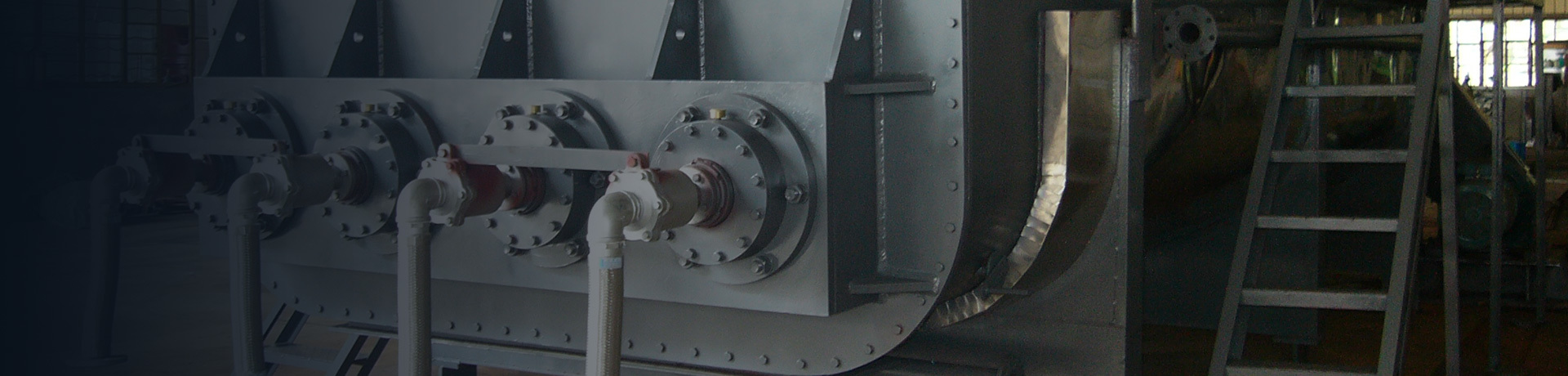

1. Multi-hole distribution plate: A core component that ensures uniform airflow distribution, prevents "channeling" or "dead zones," and is key to achieving a uniform fluidized state.

2. Hot air box: Stabilizes and equalizes the airflow before entering the distribution plate. 3. Bed: It is usually divided into several drying sections, and the air temperature and air volume in different areas can be adjusted as needed to achieve precise drying.C. Suitable Materials

1. Inorganic Salts: Wet cake drying of potassium chloride, sodium chloride, potassium sulfate, ammonium chloride, etc.

2. Chemical Raw Materials: Drying of granular materials such as sodium bicarbonate, sodium carbonate, and sodium citrate

3. Mineral Processing: Drying of wet materials such as phosphate rock powder, limestone powder, and fluorite powder

4. Food and Pharmaceuticals: Drying of low-viscosity materials such as starch, protein powder, and traditional Chinese medicine granules (material can be upgraded to food-grade 304/316L).

-

-

Specifications Processing capacity (wet cake/dry material) Device dimensions (length × width × height) Core structure parameters Operating parameters KC-LHC-150 150t/h 9.2m×3.3m×8m Fluidized bed area: 22 m2

Non-sagging grille: SUS316L, 8 mm pitch

Air box volume: 24 m³Hot air temperature: 200-300°C

Material outlet temperature: 120-170°C

Moisture removal rate: 98%

Thermal efficiency: ≥82%

Operating pressure: -500 to +300 PaKC-LHC-100 100t/h 7.5m×3m×7m Fluidized bed area: 18 m2

Non-sagging grille: SUS316L, 8 mm pitch

Air box volume: 20 m³Hot air temperature: 200-280°C

Material outlet temperature: 120-160°C

Moisture removal rate: ≥98%

Thermal efficiency: ≥80%

Operating pressure: -500 to +300 PaKC-LHC-80 80t/h 7m×2.5m×6m Fluidized bed area: 13 m2

Non-sagging grille: SUS316L, 8 mm pitch

Air box volume: 15 m³Hot air temperature: 200-280°C

Material outlet temperature: 120-160°C

Moisture removal rate: ≥98%

Thermal efficiency: ≥80%

Operating pressure: -500 to +300 PaKC-LHC-50 50t/h 6.2m×2m×5m Fluidized bed area: 10 m2

Non-sagging grille: SUS316L, 8 mm pitch

Air box volume: 15 m³Hot air temperature: 200-260°C

Material outlet temperature: 120-150°C

Moisture removal rate: ≥98%

Thermal efficiency: ≥78%

Operating pressure: -500-+300 Pa -

Previous: Pyrolysis of Oily Sludge

Your May Also Like

leave A Message

We will contact you as soon as possible