PRODUCTS

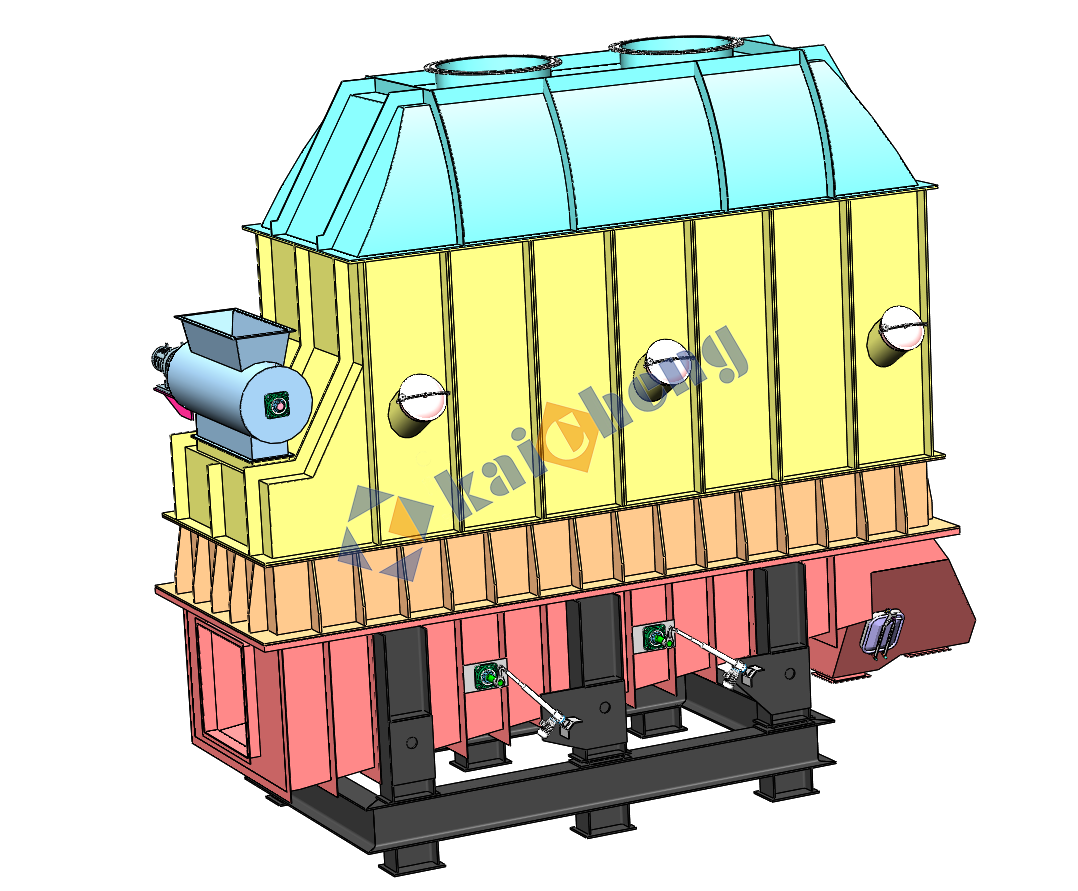

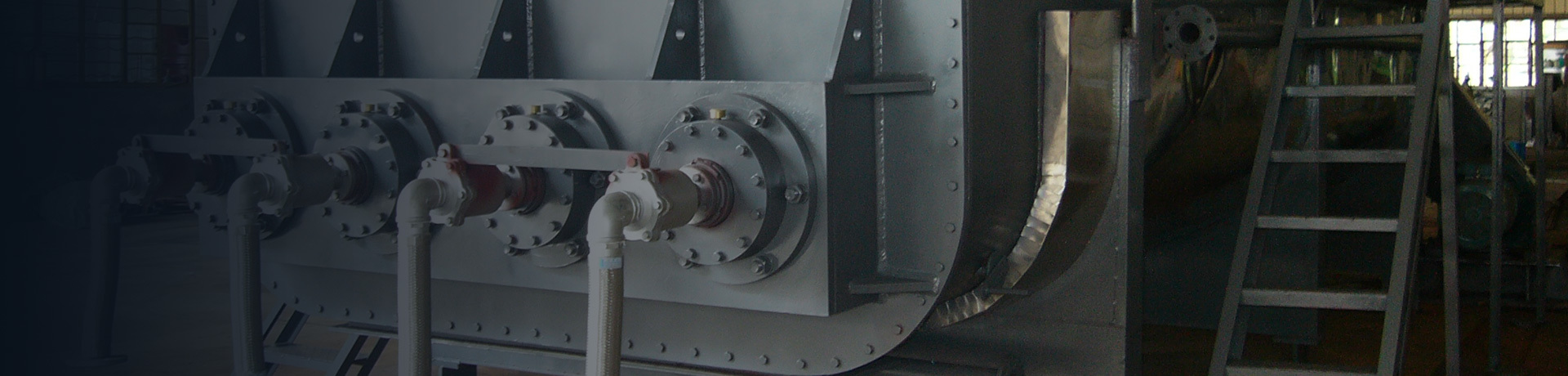

Drum Cooling Crystallization Slicer

In a cooling forming process, the molten liquid of the low melting point materials in the material tray contacts the surface of the cooling roller, forming a layer of material film on the surface of the roller. The inner part of the roler uses spray to strengthen cooling and heat transfer and reduce the materia temperature. The material film is cooled and solidified, and the formed material film is scraped off to become a sheet product.

This equipment is suitable for one-step forming of cooling flakes of low melting point materials.

Learn More