Company Profile

Guangzhou Kaicheng Drying Equipment Co.,Ltd

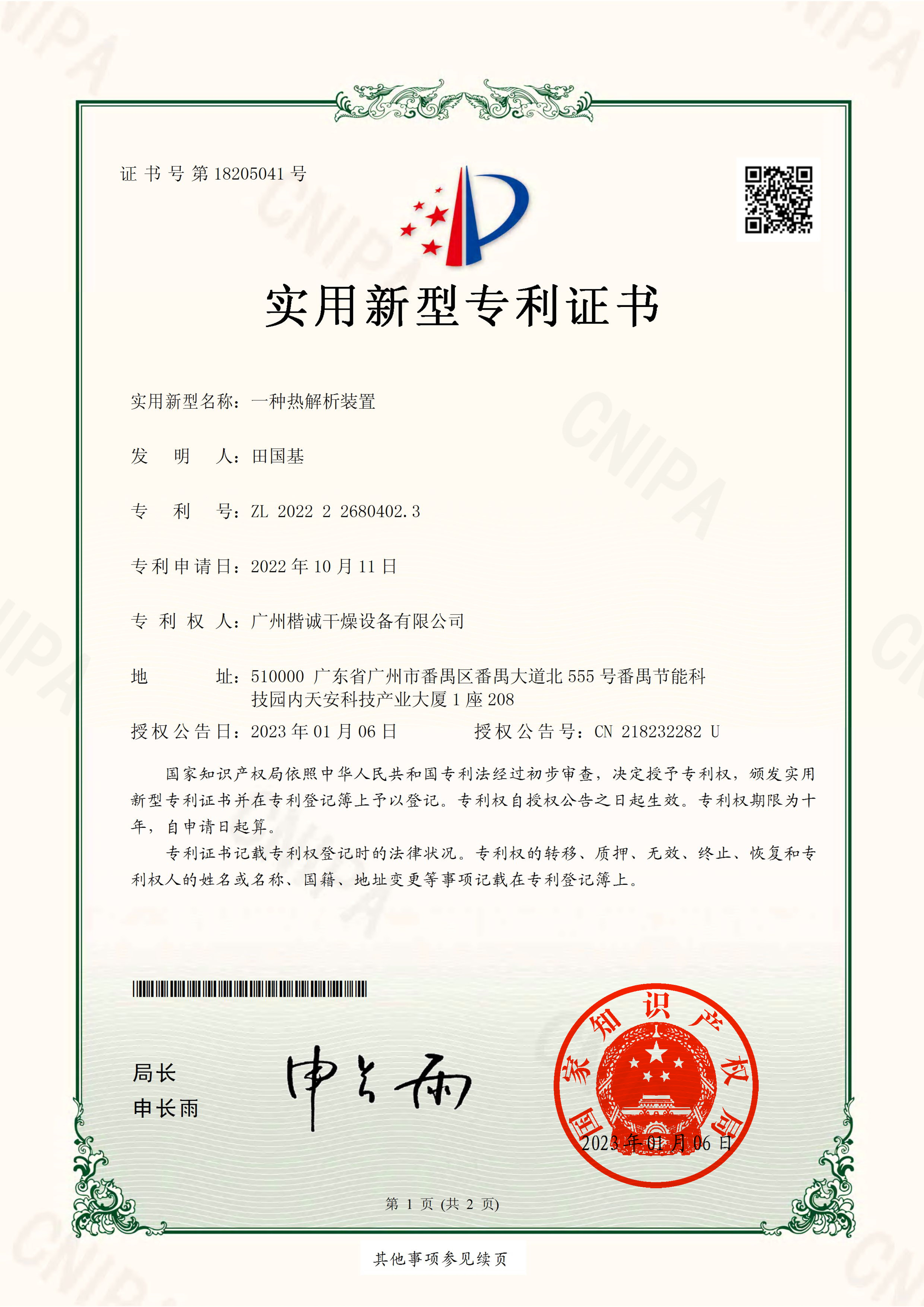

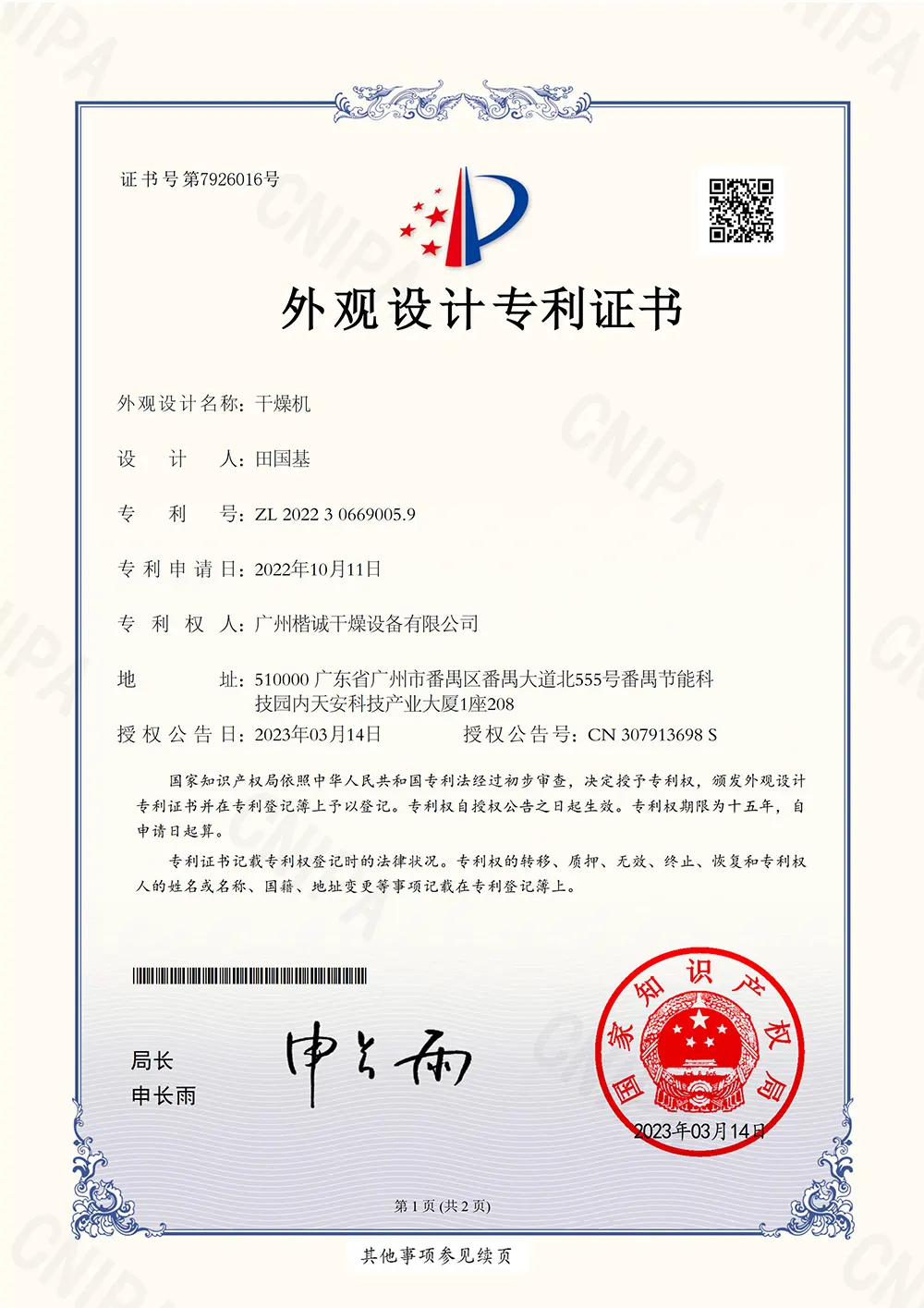

The company was founded in 2001 and is committed to the research, design, manufacture, installation and application of complete sets of equipment for deep drying and pyrolysis of sludge. The company's founder has more than 30 years of experience in the design and manufacture of drying equipment. He is one of the main researchers and key contributors to the national major equipment "localization" project, and is an expert and pioneer in the domestic industry. The first manufacturer and supplier in China to fully own independent intellectual property rights, and the headstream of domestic heat transfer-type sludge drying equipment. The company's sludge drying and sludge pyrolysis devices have been granted multiple national patents, and have obtained ISO9001:2015 quality management certification and ISO45001:2018 occupational health and safety management certification, as well as the Kaicheng brand trademark certificate. Up to now, there are more than 40 sets of complete sets of sludge drying and complete sets of sludge pyrolysis equipment applied at home and abroad, and the products are exported to Southeast Asia, South America, Europe and other countries or regions.

Participated in the first batch of national major drying equipment "localization" project and successfully put into operation the first set of sludge drying equipment in China.

The founder of the company has over thirty years of experience in designing and manufacturing drying equipment, leading the industry direction.

The company has over 500 cooperative clients both domestically and internationally, receiving unanimous praise.

The company's drying equipment is exported to over 50 countries or regions.

The company has obtained 15 patents and qualifications related to drying equipment.

Qualification honor

Why choose us

We are the first domestic sludge drying device manufacturer and supplier with completely independent intellectual property rights, and the headstream of domestic heat transfer sludge drying devices

Development History

Know more about us

Achievement Table

Looking forward to cooperating with you.

|

user |

Sludge source |

Daily Capacity tons/day |

Water Content Before Drying (%) |

Water Content After Drying (%) |

Sludge Destination After Drying |

Commissioning Date |

| The 1st phase project of Jinfeng Dyeing Group.China |

Dyeing sludge |

10 |

80 |

20~30 |

Incinerated |

March,2007 |

| The 2st phase project of Jinfeng Dyeing Group,China |

Dyeing sludge |

50 |

80 |

20~30 |

Incinerated |

November,2007 |

| The 1st phase project of Huadu Dyeing and Weaving Co., Ltd,China |

Dyeing sludge |

10 |

80 |

20~30 |

Outward transport |

January,2008 |

| The 1st phase project of Simona Tanning (Huizhou) Co., Ltd, China |

Tannery sludge |

20 |

75 |

15~20 |

Outward transport |

April,2008 |

|

Hispano Tanning Co., Ltd. Argentina |

Tannery sludge |

30 |

75 |

15~20 |

incineration |

January,2010 |

|

Dang Tu Ky Leather Co., Ltd. Vietnam |

Tannery sludge |

6 |

75 |

≤30 |

incineration |

May,2010 |

| The 1st phase project of Kam Hing International Holdings Limited,Hong Keng,China |

Dyeing sludge |

70 |

80 |

≤30 |

Incinerated |

August,2010 |

| The 2st phase project of Huadu Dyeing and Weaving Co., Ltd,China |

Dyeing sludge |

10 |

85 |

≤20 |

incineration |

August,2010 |

| The 2st phase project of Simona Tanning (Huizhou) Co.. Ltd,China |

Tannery sludge |

36 |

70 |

≤20 |

Outward transport |

August,2011 |

|

Guangdong Esquel Textile Co, Ltd, China |

Dyeing sludge |

75~80 |

60 |

≤30 |

Incinerated |

September,2012 |

|

Jacobi Carbons Lanka(PVD)Lid,Sri Lanka |

Activated carbon sludge |

15 |

60 |

≤20 |

Exterbal sales |

May,2013 |

| The 1st phase project of Kam Hing International Holdings Limited,Hong Keng,China |

Dyeing sludge |

36~40 |

80 |

≤30 |

Incinerated |

March,2014 |

|

SLG Technology Limited, Scotland |

Tannery sludge |

48~50 |

73 |

≤20 |

ncinerated |

November,2014 |

| Sinopec Group Jiujiang Petrochemical Co.. Ltd,China |

Three-sludge |

30~36 |

85 |

30 |

Hazardous |

June,2016 |

| Foshan Jialida Environmental Protection Co. Ltd. |

Dyeing sludge |

240 |

80 |

30 |

Incinerated |

November,2016 |

| A sewage treatment company in Dongguan Sludge drying section |

Municipal sludge. |

150 |

80 |

8 |

Thermolysis |

May,2020 |

| A sewage treatment company in Dongguan Sludge pyrolysis section |

Municipal sludge. |

75 |

8 |

< 0.1% |

Outward transport |

May,2020 |

| Shantou Green Power Environmental Service Co., Ltd |

Municipal sludge |

200 |

80 |

25 |

incineration |

January,2021 |

| Foshan Nanhai Xigiao Xinlong Water Treatment Co., Ltd |

Printing and |

180 |

80 |

30 |

Outward transport |

May,2021 |

| De'an jingneng Ecological and Environmental Protection Technology Co.. Ltd |

Printing and |

100 |

80 |

30 |

Outward transport |

September,2022 |

Partners

Typical user representative