GUANGZHOU KAICHENG DRYING EQUIPMENT CO.,LTD

E-mail: tgj@kchdry.com

Experts and pioneers of sludge drying and pyrolysis field in China.

explore more

GUANGZHOU KAICHENG DRYING EQUIPMENT CO.,LTD

E-mail: tgj@kchdry.com

Experts and pioneers of sludge drying and pyrolysis field in China.

explore more

GUANGZHOU KAICHENG DRYING EQUIPMENT CO.,LTD

E-mail: tgj@kchdry.com

Experts and pioneers of sludge drying and pyrolysis field in China.

explore more

what we offer

The founder is proud of

more than 30 years' experience

Dryer/Sludge Dryer/Paddle Dryer/Powder Material Dryer/High Paste Material Dryer

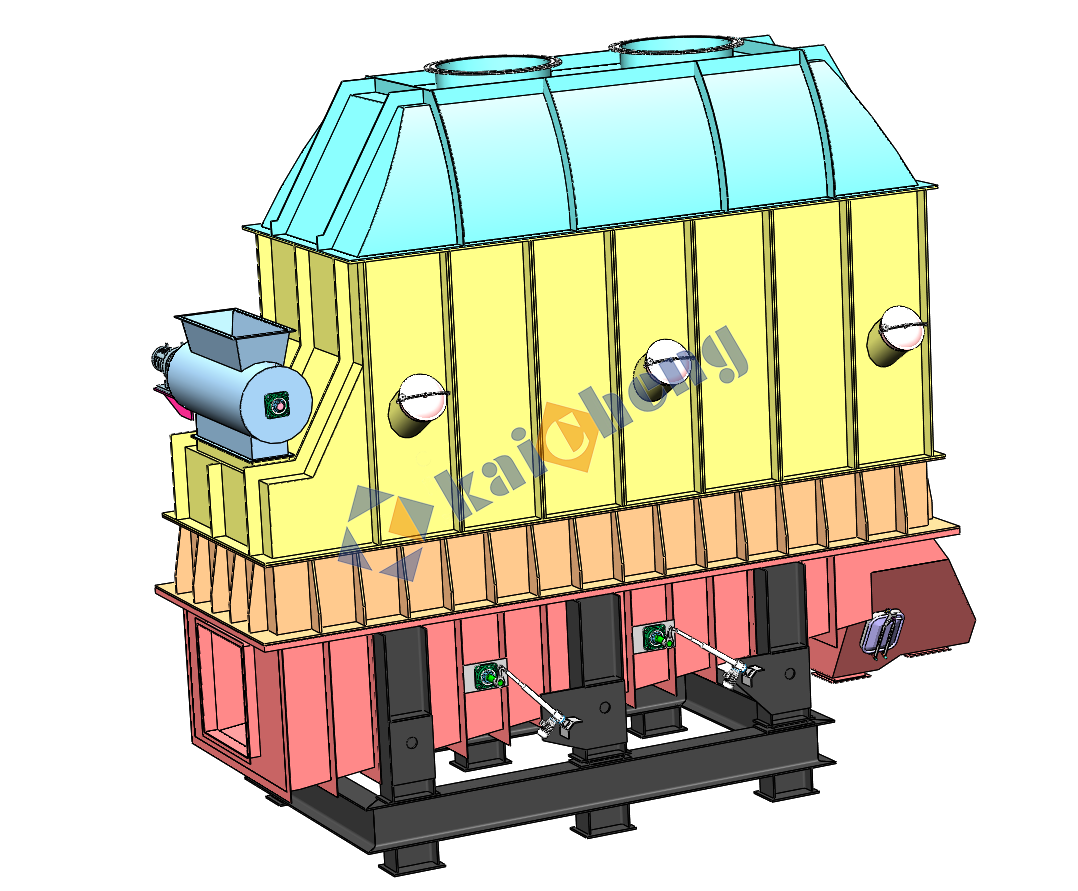

Bidirectional shear type sludge drying device with wedge-shaped blades is an indirect heating low-speed stirring dryer. There are two or four hollow rotating shafts inside the equipment, with wedge-shaped hollow blades densely arranged on the hollow shafts, and the thermal medium flows through the blades through the hollow shafts. The internal flow channel of the hot shaft is special and cleverly designed. The two shafts rotate in reverse, causing compression and relaxation between the shafts, constantly updating the heating surface of the material and greatly improving the evaporation efficiency.

learn morePyrolysis Furnace / Pyrolysis Carbonization Furnace

Under anaerobic conditions, waste organic matter undergoes thermal cracking through high-temperature carbonization, resulting in the production of valuable gas phase (pyrolysis gas) and solid phase (biochar) based on the ratio of carbon to hydrogen. Both gas phase and solid phase can be recycled. Among them, pyrolysis gas has certain combustibility and can recover energy, while biochar has porous properties and is suitable for use as an adsorbent and carbon-based fertilizer. The complete set of sludge pyrolysis equipment provides an effective way for sludge reduction, harmlessness, and resource utilization.

learn moreFilm Casting Dryer / Disc Type Liquid Dryer

It is an indirect heated liquid contact dryer, energy-saving, low-cost, process-reducing, space-saving high-performance, high-efficiency liquid dryer, using indirect heat to dry materials by conduction, its principle is similar to the drum dryer or cylinder dryer used for papermaking, but instead of drying on the curved surface of the drum or cylinder, it dries the liquid on its two planes, and its installation area is only 40% of that of the drum dryer with the same drying surface area. Many powder manufacturers and companies that want to process or recycle resources or reduce the amount of wastewater are using this method.

learn moreUrban Domestic Sewage Treatment and Reuse

Treatment methods can be divided into physical treatment methods, biological treatment methods, sludge disposal produced by sewage treatment and chemical treatment methods according to the type of water quality. They can also be divided into primary treatment, secondary treatment and advanced treatment processes according to the degree of treatment.

learn moreIndustrial Oily Wastewater Treatment and Reuse

MBBR is currently the best water treatment solution for high-strength water systems. This is mainly because of the biological nitrogen removal (BNR), which uses MBBR systems thus improving waste matter quality and increasing treatment capacity with no extra footprint growth. And you can use K1 media and MBBR media to improve water quality in MBBR systems.

learn moreRotary Cylinder Dryer / Single Channel Dryer

The rotary cylinder dryer is a large drying equipment that is directly heated, directly cooled, low-speed rotating, lifting-type material handling, and can form a spiral material curtain to improve the volumetric heat transfer coefficient. When the wet material enters the dryer, it is turned over by the scraper on the wall of the cylinder. As the cylinder rotates, it continuously turns over to form a material curtain. The hot air directly contacts the wet material inside the cylinder for heat exchange, and the moisture is vaporized. According to process requirements, hot air and wet materials can be operated in parallel or in reverse flow. The wet material is discharged from the discharge end of the dryer under the action of the spiral plate and hot air flow. The fine powder entrained by hot air is collected by a vacuum cleaner.

learn moreLarge Three-channel Drum Dryer / Large Hot Air Dryer

The process principle of the large three-channel drum dryer is a heat drying process. As the dryer cylinder rotates, the internal scraper continuously scoops up the material, forming a material curtain, allowing the material to fully contact with the hot air. The multi-channel structure design more effectively utilizes heat and space, and the residence time of materials inside the dryer is longer than that of single-channel. The unique structural principle means that the product will not be over-dried or under-dried, and the product appearance will be good.

learn moreDrying of Oily Sludge

Acid precipitation process: Adopt chemical acid precipitation + oil-bearing sludge drying method to remove oil. The core of the process technology is to break the "water-in-oil" emulsified molecular bonds in the oil sludge or oil slurry through chemical reactions, achieving oil-water separation, which naturally separates inorganic matter.Through three-phase separation, some recovered oil is finally formed. The generated inorganic sediment (a small amount of oil-bearing or trace oil-bearing) is dried with oil-bearing sludge.

learn morePyrolysis of Oily Sludge

Based on the principles of reduction, recycling, and harmlessness, we have successfully developed a pyrolysis carbonization process for oily sludge, which involves direct thermal cracking of oily sludge without separating the oil from the sludge, directly converting the oil components in the sludge into oil and gas, separating the oil and gas from the soil, and then recycling the oil and gas. This process can reduce the oil content in the soil to less than 0.3%, eliminating the hazardous waste properties of the soil. Moreover, this process is simple and has a short process flow.

learn moreHorizontal Disc Dryer

At present, the company has launched a disc dryer with a maximum heat transfer area of 518 square meters,Contains tungsten carbide spraying, wear and corrosion resistance, suitable for drying highly abrasive materialsThe material is fed into the dryer through the feed port. The working medium flows between the shell and the hollow shaft. Heat is transmitted through the jacket, the hollow shaft and the hollow disc welded on the shaft. The material is indirectly heated and dried, and the generated water vapor gathers. In the dome of the dryer, the carrier gas is carried out of the dryer. The hollow disc is perpendicular to the shaft and does not cut the material. Through the action of the propeller/agitator on the edge of the disc, the material is pushed and stirred, and the drying surface is constantly updated, thereby achieving the purpose of drying.

learn moreVector Aeration Aerobic Fermentation Reactor Device

The vector aeration aerobic fermentation reactor is a sealed integrated reactor with a high degree of intensification; Fully enclosed, energy-saving, efficient, pollution-free, flexible operation and low operating cost; It integrates feeding device, discharging device, deodorizing device and fermentation device; Using a manufacturer does not require the construction of a factory building, and one piece of equipment is equivalent to an intensive chemical factory; Equipped with a complete set of fermentation exhaust gas treatment devices, the exhaust gas produced complies with the GB14554 national standard.

learn moreSlide Silo and Square Cone Bottom Silo

The main body of the silo is a square or cone-shaped closed steel structure. The storage silo is composed of a silo body, an entrance grille/feed port, a hydraulic slide/vibration motor, a material level meter, a deodorizing air outlet/dust removal port, etc. The steel Structural parts (supporting access platforms, handrails, stairs, all connecting accessories, anchor bolts) and other accessories. The steel plate thickness, inner wall anti-corrosion and wear resistance used in the silo comply with national standards, and all welds are inspected in accordance with the Class B regulations of GBll345.

learn moreDrum Cooling Crystallization Slicer

In a cooling forming process, the molten liquid of the low melting point materials in the material tray contacts the surface of the cooling roller, forming a layer of material film on the surface of the roller. The inner part of the roler uses spray to strengthen cooling and heat transfer and reduce the materia temperature. The material film is cooled and solidified, and the formed material film is scraped off to become a sheet product. This equipment is suitable for one-step forming of cooling flakes of low melting point materials.

learn moreExplosive Chemical Cooling and Production

The reaction synthesis section in the chemical production process generates a large amount of high-temperature powder materials, which poses great difficulties in storage, packaging, and transportation. Therefore, it is necessary to cool them to room temperature or a lower safe temperature. For example, cooling emulsion explosives, NaOH, Na₂CO₃, NaHCO₃, etc.

learn moreSpiral Plate Heat Exchanger

The spiral heat exchanger has a double flow channel composed of two concentric spiral lines. The double flow channels do not interfere with each other, and the medium is in a completely counter-flow state in the flow channel. Thermal fluid generally enters from the central axis, flows from the inside to the outside, and flows out from the sides. The cold fluid enters from the outside of the side and flows inward toward the central axis to achieve counterflow. This method can achieve higher heat transfer coefficients than other types of heat exchangers. Easier to achieve temperature exchange.

learn moreTungsten Carbide Spraying Technology

The introduction of the US Plexi Tungsten Carbide Supersonic Spraying Device for spraying the outer surface of the dryer blade and the inner surface of the shell. Firstly, melt the surface of the metal using high-pressure liquid oxygen, aviation kerosene, propylene oxide and other high-temperature media. Then, nitrogen subsonic spraying of tungsten carbide onto the molten metal surface is used to achieve secondary fusion of the metal surface. This technology not only improves the wear resistance of the metal surface, but also extends the service life of the dryer by more than 15 years.

learn moreBuried Scraper Conveyor Device

The buried scraper conveyor device is divided into two types: Z-type scraper conveyor and horizontal scraper conveyor. Designed and manufactured based on the complete mapping of the scraper imported by the Japanese company Tsubaki, it uses two guide chains installed inside a closed shell to transport objects horizontally or vertically. It can transport not only ordinary powders, sludge and granular bodies, but also objects that are not easy to transport and objects with strong adhesion. Materials used: SUS304 stainless steel shell and scraper, 2Cr13 high-strength chain, HRC=45±5.

learn moreInstrumentation Agent

Act as an agent to purchase the instruments and meters needed at the project site, such as electric valves, pneumatic valves, temperature sensors, thermometers, pressure sensors, pH meters, smart water meters for sewage treatment plants, oxygen concentration detectors, H2S meters, ammonia nitrogen meters, COD meters , gas detector, etc.

learn moreCompany profile

Guangzhou Kaicheng Drying Equipment Co., Ltd.

The company was founded in 2001 and is committed to the research, design, manufacture, installation and application of complete sets of equipment for deep drying and pyrolysis of sludge.

OUR PRODUCTS ARE USED

ALL OVER THE WORLD

Years' Experience

Major Series

Countries or Regions

Application Case

Our cases

Some practical use cases of our

products

Cooperation Communication

In-depth communication

General Inquires

Our Location

1-208, Industrial Building, No. 555 North Panyu Avenue, Panyu District, Guangzhou, China

Contact us

If you are interested in our products, please contact us

Contact

Location:1-208, Industrial Building, No. 555 North Panyu Avenue, Panyu District, Guangzhou, China