Explosive Chemical Cooling and Production

The reaction synthesis section in the chemical production process generates a large amount of high-temperature powder materials, which poses great difficulties in storage, packaging, and transportation. Therefore, it is necessary to cool them to room temperature or a lower safe temperature. For example, cooling emulsion explosives, NaOH, Na₂CO₃, NaHCO₃, etc.

Product Attachments:

Keywords: Explosive Chemical Cooling and Production

- Description

- Schematic Diagram

- Parameter

- Result

-

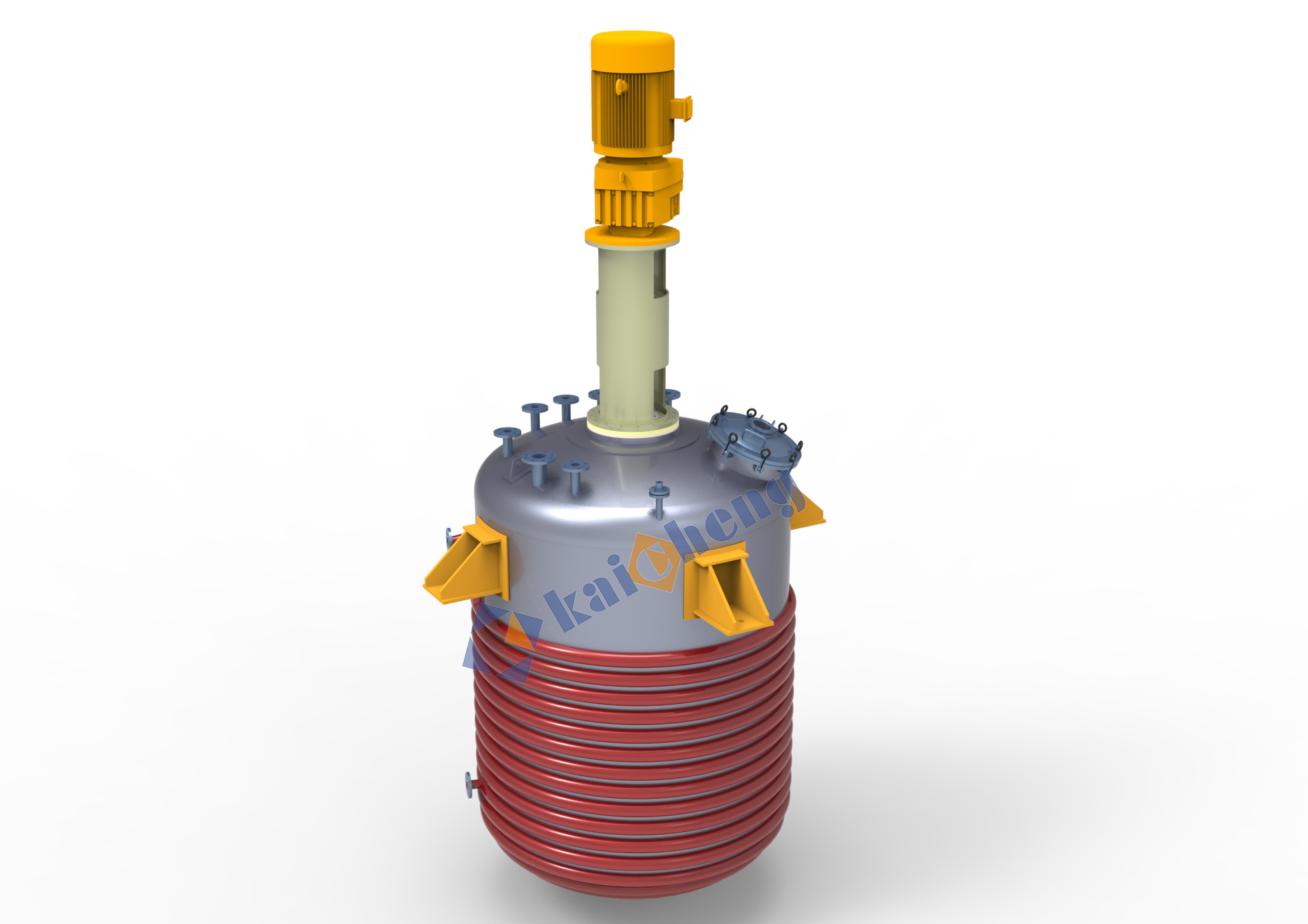

Reactor product description:

Equipment name: External half-tube reactor

Equipment volume: 50-30000L (can be configured according to user needs)

Reaction temperature: normal temperature--300 degrees

Reaction pressure: -0.1-0.7Mpa (depending on process and material requirements)

Equipment material: stainless steel, carbon steel, 321 stainless steel, special materials (acid and alkali resistant)

Mixing form: paddle type, anchor paddle type, frame type, ribbon type, dispersing disk type, combined type

Thermal medium: thermal oil heating, steam heating, hot water heating, electric heating

Others: This equipment is non-standard equipmentReactor introduction:

The broad understanding of a reactor is a stainless steel container with physical or chemical reactions. Through the structural design and parameter configuration of the container, it can realize the heating, evaporation, cooling and low-speed mixing functions required by the process. Subsequently, the pressure requirements during the reaction process also have different design requirements for the container. Production must be processed, tested and tested in strict accordance with corresponding standards. Reactors vary according to different production processes, operating conditions, etc., and have different design structures and parameters, that is, different structural styles, and are non-standard reaction vessel equipment.

Application scope:

Reactors are widely used in explosive chemical production, resin, adhesive, petrochemical, fine processing and other industries.

Features:

1. Quality: Made of high-quality stainless steel, mirror-polished appearance, using a vacuum box balance structure, the vacuum degree reaches -0.098, and the sealing quality is good.

2. Service: pre-sales one-to-one consultation, centralized use of photos or videos to report production progress, after-sales service, global access, 1-year warranty, 10-year durability, and lifetime maintenance.

3. Efficiency: Drawings can be produced in three days and goods can be shipped in one month.

4. Team: Focusing on the chemical equipment industry for more than 20 years, we have a technical team of 5 people with more than 20 years of experience.

5. We can provide the entire production line production, factory specifications, reasonable customization, and equipped with machinery suitable for you.

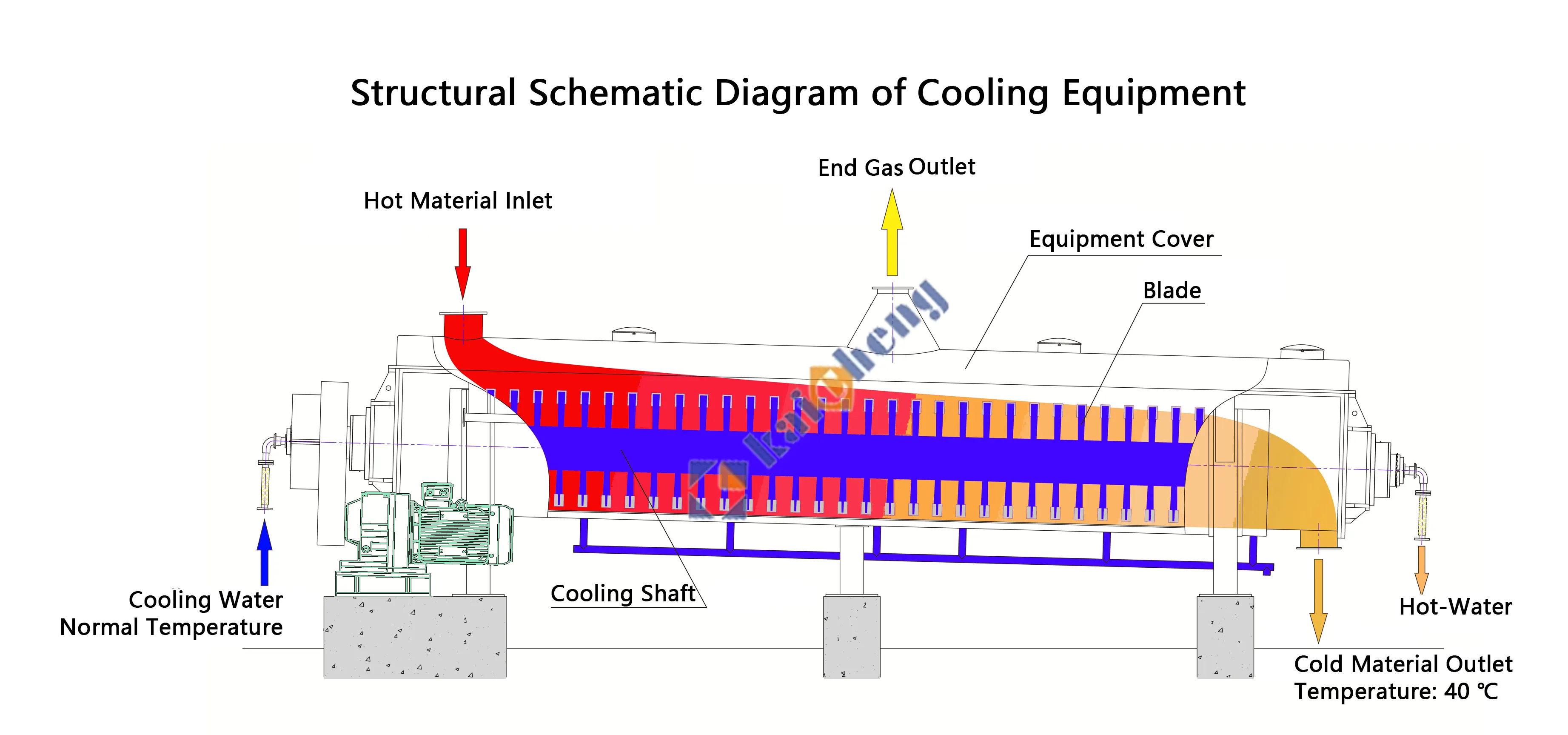

6. There are complete types of equipment, there is always one suitable for you.Cooler development background:

The reaction synthesis section in the chemical production process generates a large amount of high-temperature powder materials, which poses great difficulties in storage, packaging, and transportation. Therefore, it is necessary to cool them to room temperature or a lower safe temperature.

For example, cooling emulsion explosives, NaOH, Na₂CO₃, NaHCO₃, etc.

Equipment Characteristics:

- The technology is mature and reliable, and has more than 20 years of successful use experience

- Small footprint

- High cooling efficiency

- Large processing capacity

- No dust on site

- High quality equipment

- Short maintenance cycle

- Long service life

Using Customers:

- Shenzhen Jin'aobo Technology Co.,Ltd.: Civil emulsion explosive cooling machine

- Heilongjiang Jixi Mining Bureau No. 7 Factory: Civil blasting explosive cooler

- PetroChina Jinxi Petrochemical Co., Ltd.: NaOH cooling machine

- Southern Alkali Factory: Na₂CO₃ cooling machine

Applicable Materials:

Suitable for cooling various solid materials other than superheated air.

-

-

NO. Project Name Technical Parameters 1 Equipment volume 50L-50000L (can be designed according to requirements) 2 Motor Power 0.75kW-130kW (optional according to product performance and equipment size) 3 Stirring speed Low speed stirring: 0~300rpm, high speed stirring: 0~2800rpm 4 Speed mode Frequency converter speed regulation 5 set tempreture -20℃~300℃ 6 design pressure -0.1~1.6MPa 7 Equipment material SS316L, SS321, SS304 stainless steel, carbon steel, other materials 8 Stirring form Paddle type, anchor paddle type, frame type, ribbon type, turbine type, dispersed disc type, combined type, etc. 9 heat transfer structure Outer jacket, outer half pipe, inner coil 10 Sealed form Double-end mechanical seal, single-end mechanical seal, high-speed stirring mechanical seal, packing seal 11 heating method Hot oil circulation heating, jacketed electric heating, steam heating, hot water heating, etc. -

Previous: Drum Cooling Crystallization Slicer

Your May Also Like

leave A Message

We will contact you as soon as possible