PRODUCTS

Dryer/Sludge Dryer/Paddle Dryer/Powder Material Dryer/High Paste Material Dryer

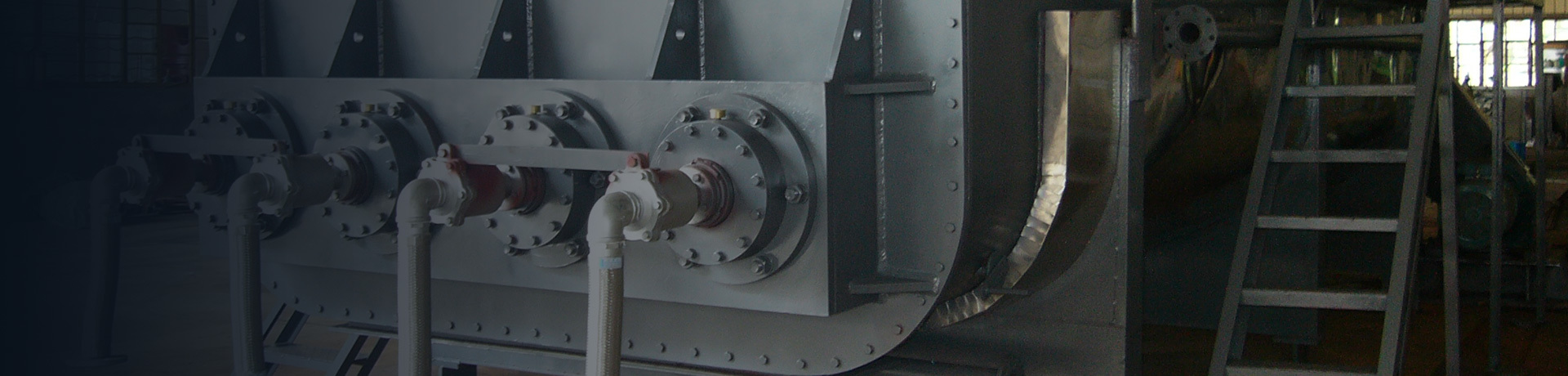

Bidirectional shear type sludge drying device with wedge-shaped blades is an indirect heating low-speed stirring dryer.

There are two or four hollow rotating shafts inside the equipment, with wedge-shaped hollow blades densely arranged on the hollow shafts, and the thermal medium flows through the blades through the hollow shafts.

The internal flow channel of the hot shaft is special and cleverly designed. The two shafts rotate in reverse, causing compression and relaxation between the shafts, constantly updating the heating surface of the material and greatly improving the evaporation efficiency.

Learn More

Pyrolysis Furnace / Pyrolysis Carbonization Furnace

Under anaerobic conditions, waste organic matter undergoes thermal cracking through high-temperature carbonization, resulting in the production of valuable gas phase (pyrolysis gas) and solid phase (biochar) based on the ratio of carbon to hydrogen. Both gas phase and solid phase can be recycled.

Among them, pyrolysis gas has certain combustibility and can recover energy, while biochar has porous properties and is suitable for use as an adsorbent and carbon-based fertilizer.

The complete set of sludge pyrolysis equipment provides an effective way for sludge reduction, harmlessness, and resource utilization.

Learn More

Film Casting Dryer / Disc Type Liquid Dryer

It is an indirect heated liquid contact dryer, energy-saving, low-cost, process-reducing, space-saving high-performance, high-efficiency liquid dryer, using indirect heat to dry materials by conduction, its principle is similar to the drum dryer or cylinder dryer used for papermaking, but instead of drying on the curved surface of the drum or cylinder, it dries the liquid on its two planes, and its installation area is only 40% of that of the drum dryer with the same drying surface area. Many powder manufacturers and companies that want to process or recycle resources or reduce the amount of wastewater are using this method.

Learn More

Urban Domestic Sewage Treatment and Reuse

Treatment methods can be divided into physical treatment methods, biological treatment methods, sludge disposal produced by sewage treatment and chemical treatment methods according to the type of water quality. They can also be divided into primary treatment, secondary treatment and advanced treatment processes according to the degree of treatment.

Learn More

Industrial Oily Wastewater Treatment and Reuse

MBBR is currently the best water treatment solution for high-strength water systems. This is mainly because of the biological nitrogen removal (BNR), which uses MBBR systems thus improving waste matter quality and increasing treatment capacity with no extra footprint growth. And you can use K1 media and MBBR media to improve water quality in MBBR systems.

Learn More

Rotary Cylinder Dryer / Single Channel Dryer

The rotary cylinder dryer is a large drying equipment that is directly heated, directly cooled, low-speed rotating, lifting-type material handling, and can form a spiral material curtain to improve the volumetric heat transfer coefficient.

When the wet material enters the dryer, it is turned over by the scraper on the wall of the cylinder. As the cylinder rotates, it continuously turns over to form a material curtain. The hot air directly contacts the wet material inside the cylinder for heat exchange, and the moisture is vaporized.

According to process requirements, hot air and wet materials can be operated in parallel or in reverse flow. The wet material is discharged from the discharge end of the dryer under the action of the spiral plate and hot air flow. The fine powder entrained by hot air is collected by a vacuum cleaner.

Learn More

Large Three-channel Drum Dryer / Large Hot Air Dryer

The process principle of the large three-channel drum dryer is a heat drying process. As the dryer cylinder rotates, the internal scraper continuously scoops up the material, forming a material curtain, allowing the material to fully contact with the hot air.

The multi-channel structure design more effectively utilizes heat and space, and the residence time of materials inside the dryer is longer than that of single-channel.

The unique structural principle means that the product will not be over-dried or under-dried, and the product appearance will be good.

Learn More

Complete set of dryer for processing 500 tons of stale domestic waste/fresh domestic waste per day

In the city where we live, domestic waste is generated every day. As time goes by, old domestic waste/fresh domestic waste will pile up like a mountain, which not only occupies a lot of land resources, but also causes environmental pollution. Therefore, it is an urgent task to treat and reuse old domestic waste/fresh domestic waste.

Learn More

Slime Dryer / Mineral Powder Dryer / Mineral Dryer

To process these large amounts of mineral powder, minerals, and sludge, a large dryer is needed for drying.

We provide dryers with a maximum processing capacity of 500-720t/d for customers to choose.

Learn More

At present, the company has launched a disc dryer with a maximum heat transfer area of 518 square meters,Contains tungsten carbide spraying, wear and corrosion resistance, suitable for drying highly abrasive materialsThe material is fed into the dryer through the feed port. The working medium flows between the shell and the hollow shaft. Heat is transmitted through the jacket, the hollow shaft and the hollow disc welded on the shaft. The material is indirectly heated and dried, and the generated water vapor gathers. In the dome of the dryer, the carrier gas is carried out of the dryer. The hollow disc is perpendicular to the shaft and does not cut the material. Through the action of the propeller/agitator on the edge of the disc, the material is pushed and stirred, and the drying surface is constantly updated, thereby achieving the purpose of drying.

Learn More

Acid precipitation process: Adopt chemical acid precipitation + oil-bearing sludge drying method to remove oil.

The core of the process technology is to break the "water-in-oil" emulsified molecular bonds in the oil sludge or oil slurry through chemical reactions, achieving oil-water separation, which naturally separates inorganic matter.Through three-phase separation, some recovered oil is finally formed.

The generated inorganic sediment (a small amount of oil-bearing or trace oil-bearing) is dried with oil-bearing sludge.

Learn More

Based on the principles of reduction, recycling, and harmlessness, we have successfully developed a pyrolysis carbonization process for oily sludge, which involves direct thermal cracking of oily sludge without separating the oil from the sludge, directly converting the oil components in the sludge into oil and gas, separating the oil and gas from the soil, and then recycling the oil and gas. This process can reduce the oil content in the soil to less than 0.3%, eliminating the hazardous waste properties of the soil. Moreover, this process is simple and has a short process flow.

Learn More