Chicken manure before fermentation has a moisture content of 80~90%

Vector Aeration Aerobic Fermentation Reactor Device

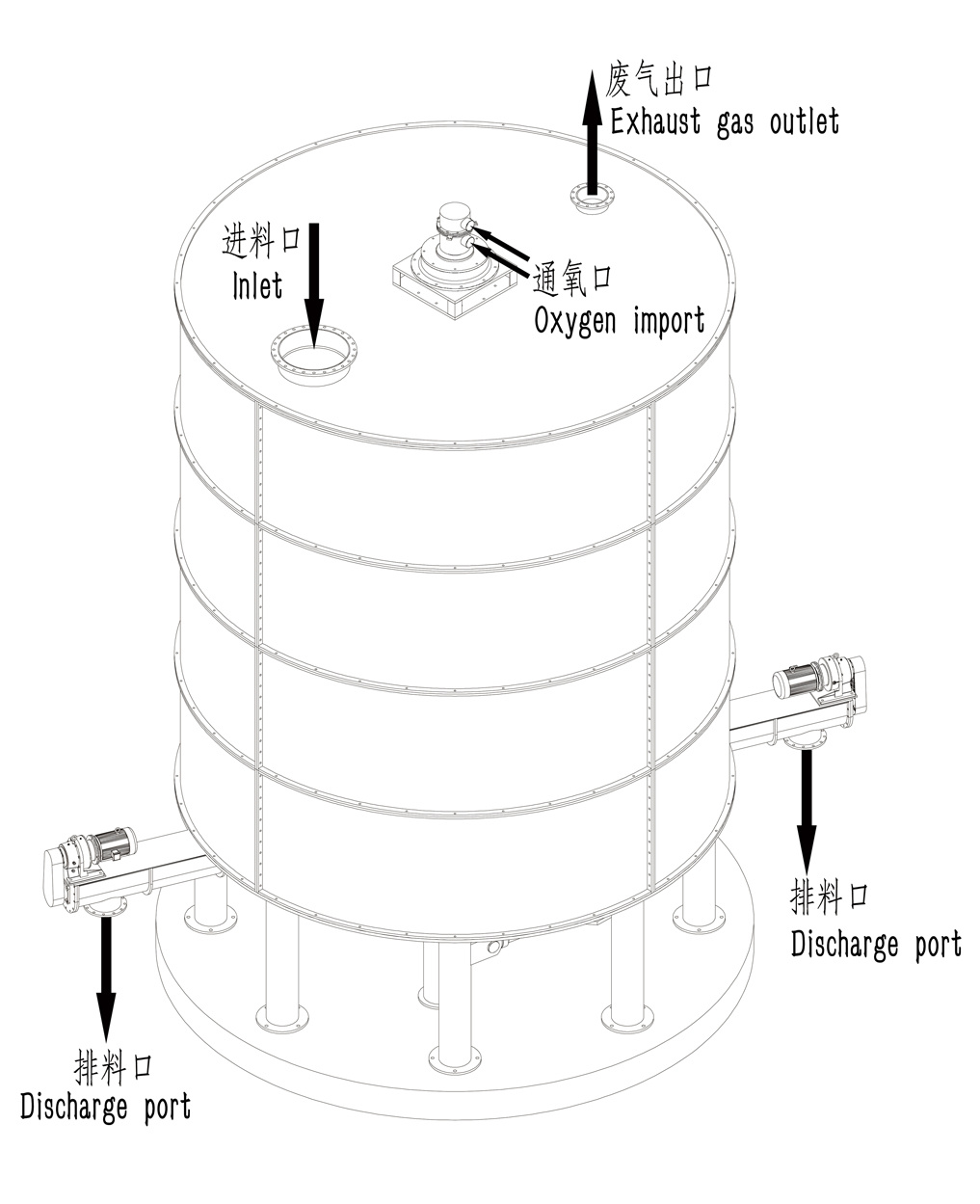

The vector aeration aerobic fermentation reactor is a sealed integrated reactor with a high degree of intensification; Fully enclosed, energy-saving, efficient, pollution-free, flexible operation and low operating cost; It integrates feeding device, discharging device, deodorizing device and fermentation device; Using a manufacturer does not require the construction of a factory building, and one piece of equipment is equivalent to an intensive chemical factory; Equipped with a complete set of fermentation exhaust gas treatment devices, the exhaust gas produced complies with the GB14554 national standard.

Product Attachments:

Keywords: Vector Aeration Aerobic Fermentation Reactor Device

- Description

- Schematic Diagram

- Parameter

- Result

-

Features:

The vector aeration aerobic fermentation reactor is a sealed integrated reactor with a high degree of intensification;

Fully enclosed, energy-saving, efficient, pollution-free, flexible operation and low operating cost;

It integrates feeding device, discharging device, deodorizing device and fermentation device;

Using a manufacturer does not require the construction of a factory building, and one piece of equipment is equivalent to an intensive chemical factory;

Equipped with a complete set of fermentation exhaust gas treatment devices, the exhaust gas produced complies with the GB14554 national standard.

Adaptable Materials:

1. Fermentation treatment of livestock and poultry feces

2. Fermentation treatment of kitchen leftovers

3. Sludge fermentation treatment in small urban municipal sewage treatment plants

Process Advantages:

Vector aeration is a directional, timing, quantitative, fixed-layer and dynamically transposable aeration device. Materials are balancedly oxygenated in the equipment. Balanced fermentation realizes various processes such as sterilization and fertilizer efficiency balance during the fermentation process. The process is short and takes up only The land area is small and the civil construction cost is low. Realizing waste reuse in a circular economy.

1. For livestock and poultry manure, nitrogen, phosphorus and potassium can be balanced during the fermentation process. The moisture content of the product coming out of the fermenter is lower than 30-35%, and it is directly granulated into high-efficiency organic fertilizer;

2. For food waste, it can be directly used as high-efficiency flower fertilizer and nutrient soil after fermentation treatment;

3. For the sludge from small urban municipal sewage treatment plants, organic matter is added for fermentation. The product has no secondary pollution and can be directly used as organic nutrient soil. Reduce the cost of sludge transportation.

-

-

Specifications and models Fermentation cycle (days) Processing capacity (tons/24 hours) Silo diameter Installed power Operating power kitchen waste livestock and poultry manure kitchen waste livestock and poultry manure mm kW kW TC-10 3-5 5-7 0.6-1.5 1.2-1.6 2060 13.6 6.2 TC-15 3-5 5-7 0.8-2 1.8-2.4 2340 14.95 8.2 TC-25 3-5 5-7 1.5-3 1.5-3 3200 20.65 9.375 TC-50 3-5 5-7 4-6 4-6 3800 23.65 14 TC-100 3-5 5-7 14-22 16-24 5300 33.9 23.9 The processing capacity of each specification is related to the annual average temperature of the installation site

The processing capacity of each specification is also related to the material itself

Sludge treatment requires the addition of organic matter as a fermentation supplement

-

Application Performance:

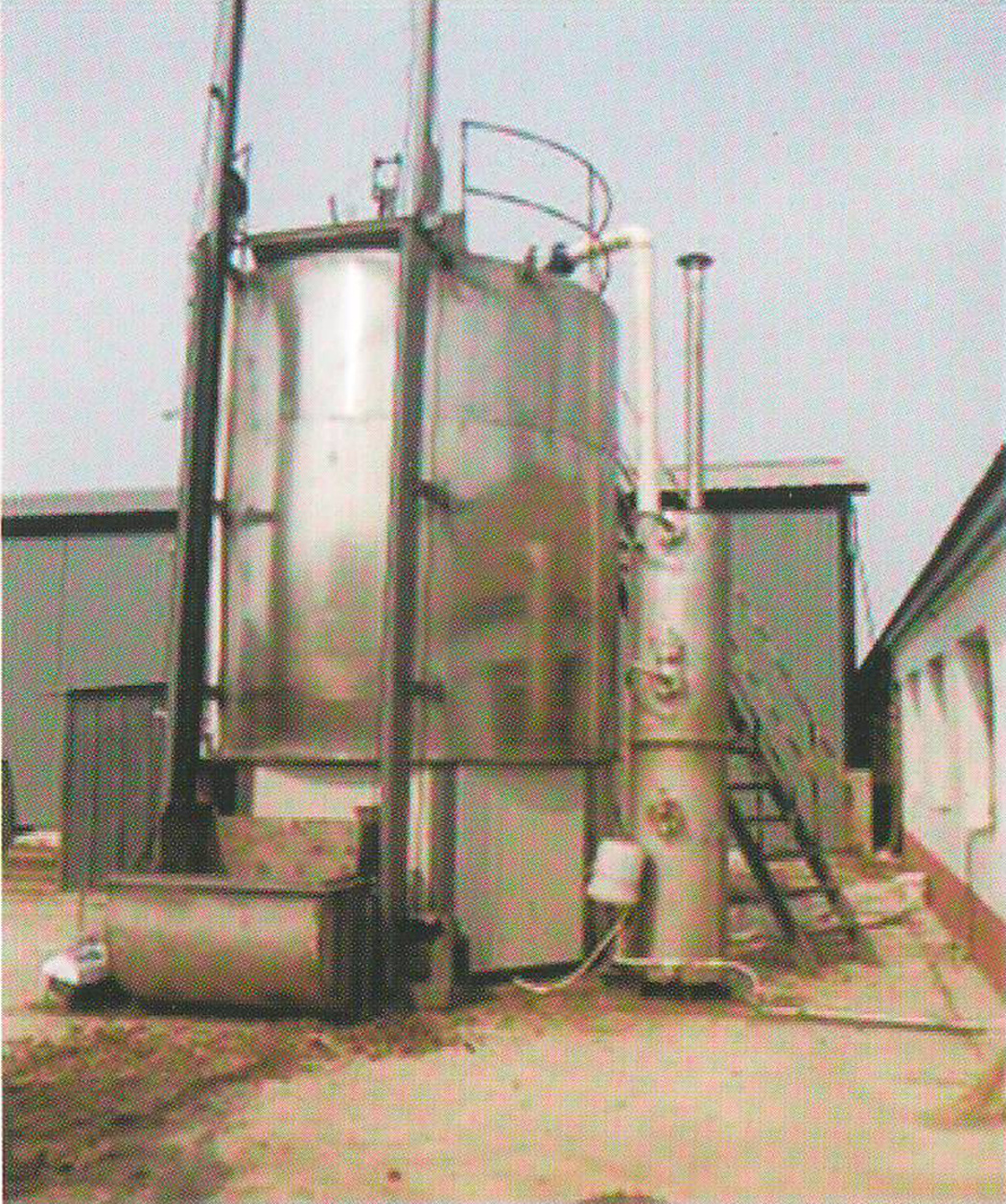

The TC-25 (full volume: 25m³) vector aeration aerobic fermentation reactor developed by Guangzhou Kaicheng was successfully commissioned in an organic fertilizer factory in Changziying, Daxing District, Beijing.

Your May Also Like

leave A Message

We will contact you as soon as possible