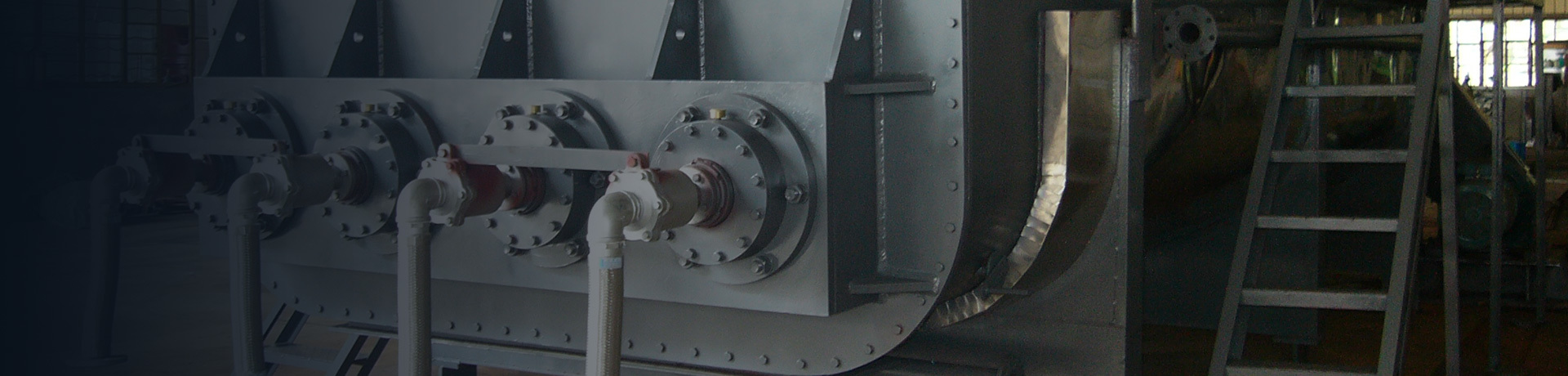

Horizontal Disc Dryer

At present, the company has launched a disc dryer with a maximum heat transfer area of 518 square meters,Contains tungsten carbide spraying, wear and corrosion resistance, suitable for drying highly abrasive materialsThe material is fed into the dryer through the feed port. The working medium flows between the shell and the hollow shaft. Heat is transmitted through the jacket, the hollow shaft and the hollow disc welded on the shaft. The material is indirectly heated and dried, and the generated water vapor gathers. In the dome of the dryer, the carrier gas is carried out of the dryer. The hollow disc is perpendicular to the shaft and does not cut the material. Through the action of the propeller/agitator on the edge of the disc, the material is pushed and stirred, and the drying surface is constantly updated, thereby achieving the purpose of drying.

Product Attachments:

Keywords: Horizontal Disc Dryer

- Description

- Schematic Diagram

- Parameter

- Result

-

At present, the company has launched a disc dryer with a maximum heat transfer area of 518 square meters,Contains tungsten carbide spraying, wear and corrosion resistance, suitable for drying highly abrasive materials

Application scope of horizontal disc dryer:

Sludge (municipal, chemical, papermaking, petroleum, etc.), food residues, medicine residues, wine residues, fertilizers, resins, etc.

Working principle of horizontal disc dryer:

The material is fed into the dryer through the feed port. The working medium flows between the shell and the hollow shaft. Heat is transmitted through the jacket, the hollow shaft and the hollow disc welded on the shaft. The material is indirectly heated and dried, and the generated water vapor gathers. In the dome of the dryer, the carrier gas is carried out of the dryer. The hollow disc is perpendicular to the shaft and does not cut the material. Through the action of the propeller/agitator on the edge of the disc, the material is pushed and stirred, and the drying surface is constantly updated, thereby achieving the purpose of drying.

Horizontal disc dryer components: stator-rotor-driving device

Stator: The stator of the dryer is approximately cylindrical in shape, with a dome on the top to provide volume space for carrier gas and water vapor. It is also equipped with an exhaust gas outlet and an inspection window to facilitate equipment maintenance and repair. The stator end plate is flange mounted for easy maintenance, and the end plate is also used to fix the rotor bearings.

Rotor: The load-bearing part of the entire dryer, consisting of a hollow shaft and a set of hollow discs. In order to improve the sturdiness of the disc, several groups of support rods are arranged in a ring shape in the hollow inner cavity. A propeller/agitator is installed on the outer edge of the disc, which simultaneously propels and stirs the material.

Driving device: It consists of an embedded reduction gearbox, a coupler and a motor, etc., and is used to drive the rotor to rotate slowly.

Product features of horizontal disc dryer:

1. The system load is small, the reliability is high, the continuous operation is good, and it can operate day and night. It is suitable for long-term and large-volume material drying.

2. The oxygen content, temperature and dust amount are low during operation, and the system safety is good

3. Large heat transfer area, compact structure, small dimensions, and good wear resistance.

4. Few auxiliary equipment and simple system.

5. Set up a carrier gas supply port, which requires less auxiliary air and requires less exhaust gas treatment equipment.

6. Can be used in semi-drying process or fully drying process.

7. Use low-grade saturated steam heat transfer medium

8. Solid structure, less maintenance, easy maintenance, and durable. -

-

序号/NO./серийный номер 设备规格/Equipment Specifications/Технические характеристики оборудования 蒸发量/Evaporation/Испарение 圆盘直径/Disk diameter/Диаметр диска 圆盘个数/Number of discs/Количество дисков 1 KCH-1835 0.8-0.9t/h 1.8 35 2 KCH-2040 0.9-1.2t/h 2.0 40 2 KCH-2055 1.5-2.0t/h 2.0 55 3 KCH-2060 2.5-3.0t/h 2.0 60 4 KCH-2265 3.2-3.5t/h 2.2 65 5 KCH-2270 4.5-5.0t/h 2.2 70 -

Your May Also Like

leave A Message

We will contact you as soon as possible