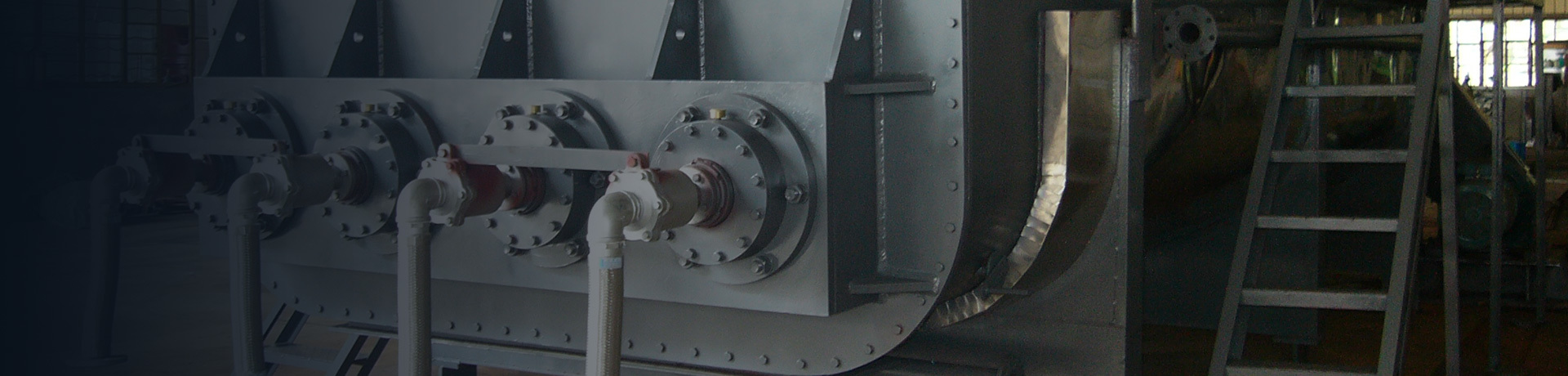

Tungsten Carbide Spraying on the Inner Surface of the Shell

Tungsten Carbide Spraying Technology

The introduction of the US Plexi Tungsten Carbide Supersonic Spraying Device for spraying the outer surface of the dryer blade and the inner surface of the shell. Firstly, melt the surface of the metal using high-pressure liquid oxygen, aviation kerosene, propylene oxide and other high-temperature media. Then, nitrogen subsonic spraying of tungsten carbide onto the molten metal surface is used to achieve secondary fusion of the metal surface. This technology not only improves the wear resistance of the metal surface, but also extends the service life of the dryer by more than 15 years.

Product Attachments:

Keywords: Tungsten Carbide Spraying Technology

- Description

- Schematic Diagram

- Parameter

- Result

-

Technology:

The introduction of the US Plexi Tungsten Carbide Supersonic Spraying Device for spraying the outer surface of the dryer blade and the inner surface of the shell.

Firstly, melt the surface of the metal using high-pressure liquid oxygen, aviation kerosene, propylene oxide and other high-temperature media.

Then, nitrogen subsonic spraying of tungsten carbide onto the molten metal surface is used to achieve secondary fusion of the metal surface.

This technology not only improves the wear resistance of the metal surface, but also extends the service life of the dryer by more than 15 years.Equipment Characteristics:

Video of Tungsten Carbide Spraying Process:

-

-

-

Tungsten Carbide Spray Blade Coating Thickness of 90 Microns

Previous: Spiral Plate Heat Exchanger

Your May Also Like

leave A Message

We will contact you as soon as possible