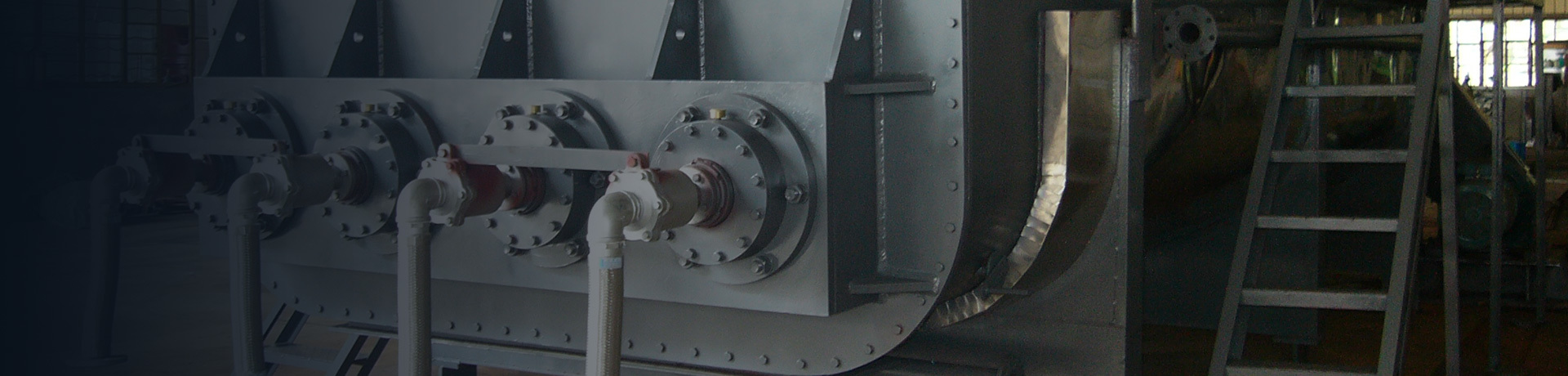

Pyrolysis Furnace / Pyrolysis Carbonization Furnace

Under anaerobic conditions, waste organic matter undergoes thermal cracking through high-temperature carbonization, resulting in the production of valuable gas phase (pyrolysis gas) and solid phase (biochar) based on the ratio of carbon to hydrogen. Both gas phase and solid phase can be recycled. Among them, pyrolysis gas has certain combustibility and can recover energy, while biochar has porous properties and is suitable for use as an adsorbent and carbon-based fertilizer. The complete set of sludge pyrolysis equipment provides an effective way for sludge reduction, harmlessness, and resource utilization.

Product Attachments:

Keywords: Pyrolysis Furnace / Pyrolysis Carbonization Furnace

- Description

- Schematic Diagram

- Parameter

- Result

-

Working Principle:

Under anaerobic conditions, waste organic matter undergoes thermal cracking through high-temperature carbonization, resulting in the production of valuable gas phase (pyrolysis gas) and solid phase (biochar) based on the ratio of carbon to hydrogen. Both gas phase and solid phase can be recycled.

Among them, pyrolysis gas has certain combustibility and can recover energy, while biochar has porous properties and is suitable for use as an adsorbent and carbon-based fertilizer.

The complete set of sludge pyrolysis equipment provides an effective way for sludge reduction, harmlessness, and resource utilization.

Equipment Characteristics:

- Alternative technologies for incineration processes, effectively preventing the generation of dioxins.

- Under certain conditions, energy self-sufficiency can be achieved, and the generated pyrolysis gas can be recycled and used as fuel for thermal furnaces, greatly reducing operating costs.

- Adopting multi burner furnace heating to ensure stable and reliable effective pyrolysis treatment of sludge.

- Unique sealing structure design and nitrogen protection system reduce safety hazards

- Compared to incineration systems, carbon dioxide emissions are only one tenth of them, which is in line with the emission reduction significance of the global "dual carbon" policy.

- The final product is biochar (fixed carbon), with a carbon content of 61%, a water content of ≤ 0.1%, and an organic content of ≤ 0.3%.

- Adopting a PLC fully automatic control system to reduce labor costs.

Adapt to Materials:

- Oily sludge, oil mud, drilling fluid, waste engine oil

- Waste organic solvents, paint, and paint residue

- Various mixed unknown organic mixtures

- Leather products: Shattered leather foam, peeled leather, leather residue

- Kitchen waste

- Domestic organic waste

- Various waste organic matter, hazardous waste organic matter

-

- Feed: The material enters the pyrolysis furnace from the wet inlet for pyrolysis.

- Discharge: the biochar after pyrolysis is discharged from the discharge end of the pyrolysis furnace.

- Pyrolysis gas: The pyrolysis gas generated during the pyrolysis process can replace natural gas as fue and return to the pyrolysis furnace for combustion.

- Flue gas: The flue gas is separated by a cyclone and discharged by a fan from the furnace.

- The bottom of the pyrolysis furnace is equipped with a natural gas burner, which can perform high-temperature and low-temperature pyrolysis. Automatically adjust to high, low, or ceasefire based on temperature control.

-

Model Number Single-machine Capacity KC-RJX-10T

10t/d

KC-RJX-15T

15t/d

KC-RJX-25T

25t/d

KC-RJX-60T

60t/d

KC-RJX-120T

120t/d

-

(The picture on the left) is a photo of the sludge after drying. The sludge is dried from a moisture content of 80% to a moisture content of 8% through a dryer.

(The picture on the right) is a photo of sludge after pyrolysis. The dried sludge with a moisture content of 8% is pyrolyzed in a pyrolysis furnace. Biochar is generated after pyrolysis (the carbon content of biochar is 61%, and the moisture content is < 0.1%, organic matter content <0.3%).

Your May Also Like

leave A Message

We will contact you as soon as possible