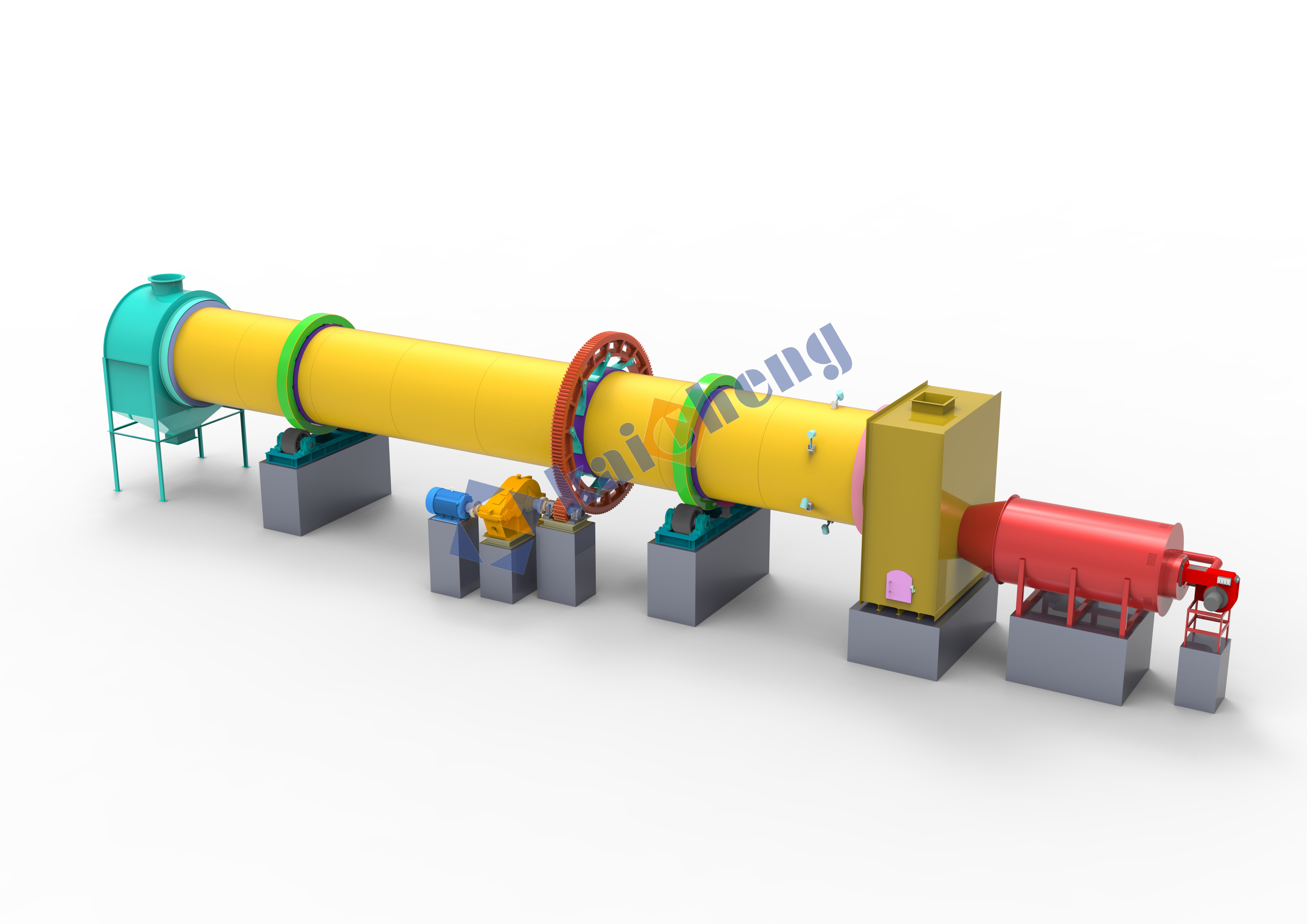

Rotary Cylinder Dryer / Single Channel Dryer

The rotary cylinder dryer is a large drying equipment that is directly heated, directly cooled, low-speed rotating, lifting-type material handling, and can form a spiral material curtain to improve the volumetric heat transfer coefficient. When the wet material enters the dryer, it is turned over by the scraper on the wall of the cylinder. As the cylinder rotates, it continuously turns over to form a material curtain. The hot air directly contacts the wet material inside the cylinder for heat exchange, and the moisture is vaporized. According to process requirements, hot air and wet materials can be operated in parallel or in reverse flow. The wet material is discharged from the discharge end of the dryer under the action of the spiral plate and hot air flow. The fine powder entrained by hot air is collected by a vacuum cleaner.

Product Attachments:

Keywords: Rotary Cylinder Dryer / Single Channel Dryer

- Description

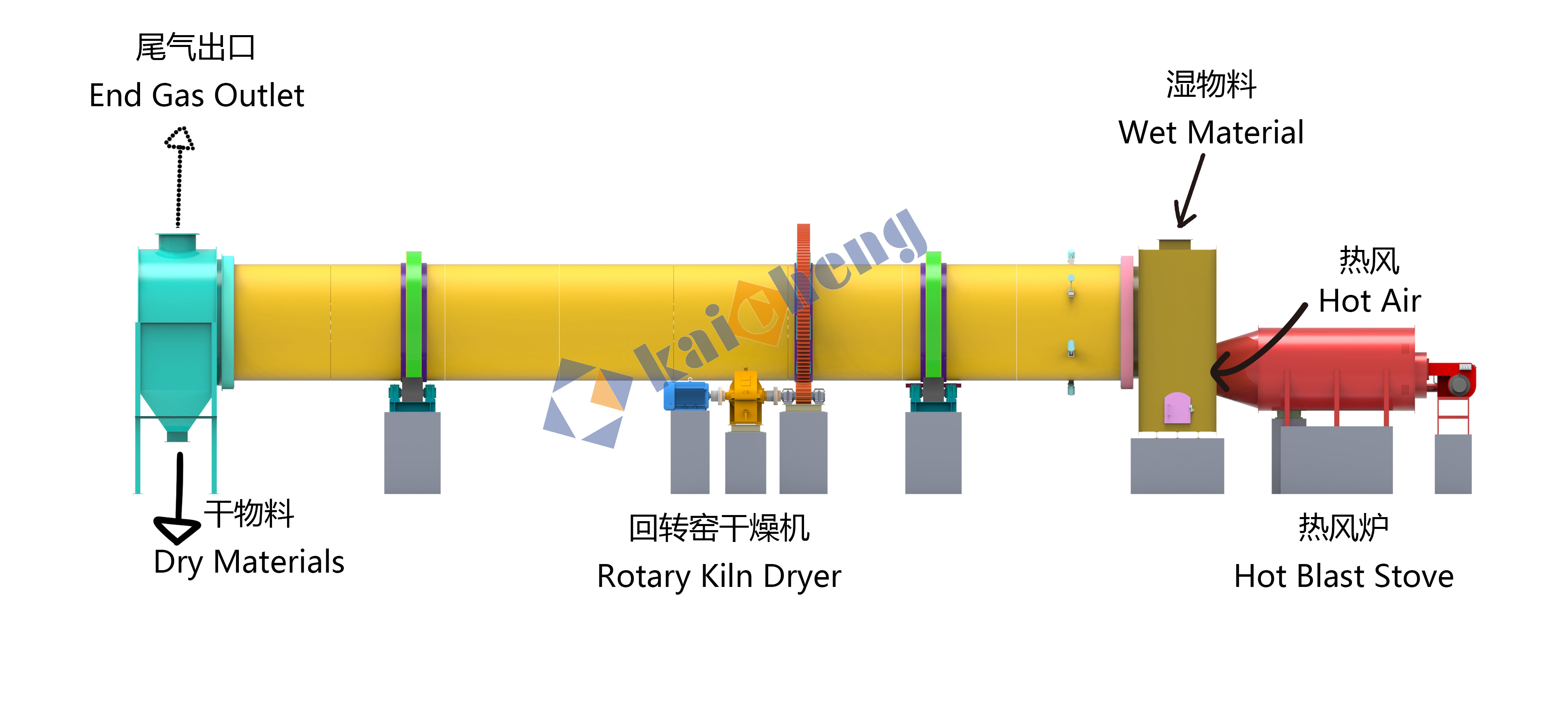

- Schematic Diagram

- Parameter

- Result

-

Working Principle:

The rotary cylinder dryer is a large drying equipment that is directly heated, directly cooled, low-speed rotating, lifting-type material handling, and can form a spiral material curtain to improve the volumetric heat transfer coefficient.When the wet material enters the dryer, it is turned over by the scraper on the wall of the cylinder. As the cylinder rotates, it continuously turns over to form a material curtain. The hot air directly contacts the wet material inside the cylinder for heat exchange, and the moisture is vaporized.

According to process requirements, hot air and wet materials can be operated in parallel or in reverse flow. The wet material is discharged from the discharge end of the dryer under the action of the spiral plate and hot air flow. The fine powder entrained by hot air is collected by a vacuum cleaner.

Equipment Characteristics:

- Large production capacity and wide adaptability

- Drying and cooling are operated in the same machine without interference

- The resistance of hot air flow in the dryer cylinder is small, reducing power consumption

- Flexible temperature adjustment, allowing high and low temperature linkage operation

- Stable operation, good uniformity of the dried product

- Full set of British APV technology, safe and reliable

Adapt to Materials:

- Chemical industry: calcium hydrogen phosphate, phosphate fertilizer, ammonium sulfate, urea, potassium dichromate, calcium propionate, activated clay, magnetic powder, graphite, calcium carbonate, etc.

- Mineral products: blast furnace slag, coal, carbide slag, metal powder, bentonite, bauxite, manganese ore, pyrite, limestone, peat, etc.

- Feed industry: drying and cooling of representative material cattle bone particles,feed-grade meat and bone meal, medicine residue, distiller's grains, activated sludge, etc.

- Domestic waste industry: waste paper, waste furniture, waste silk, viscose blocks, waste pulp, fiberglass scraps, PE film, polyester film, mortar (a mixture of silica and resin, semi-solid), solid waste (fruit residue), waste packaging, waste textiles, and kitchen waste.

- Old waste: organic waste such as landfill waste, piled waste, mineralized waste or stock waste, food scraps, abandoned plants, livestock waste, etc.

Special note: Since the composition and shape of domestic waste and stale waste are diverse, and the dryer cannot enter large-volume integral materials, the harmless and resource-based treatment and reuse of domestic waste cannot be separated from the initial effective crushing tool.

Before drying, customers are required to crush it before drying. As shown in the figure below, the comparison before and after crushing

Project Case:

Customer: Rousselot (Guangdong) Gelatin Co., Ltd.

Meat and Bone Pellet Drying/Cooling Machine Site

Single-unit Capacity

Equipment Specifications

Commissioning Date

6t/h

φ1.4x15m

2001.04

Customer: Foshan Shunde Jinfeng Thermal Energy Co., Ltd.

Polyethylene and Polypropylene Recycled Plastic Rotary Drum Dryer on Site

Single-unit Capacity

Equipment Specifications

Commissioning Date

1t/h

φ1x15m

2007.03

Customer: Guangzhou Nanxi Chemical Plant

Complete Equipment Site of Basic Copper Chloride Drying Rotary Kiln

Single-unit Capacity

Equipment Specifications

Commissioning Date

0.5t/h

φ0.8x10m

2004.08

-

-

Material Type

Single-unit Capacity

Feed Moisture Content End Moisture Content Dryer Specifications Cow Bone Granules

6t/h

38% 9% φ1.4x15m Cow Bone Granules

1.5t/h

38% 9% φ0.8x12m Basic Copper Chloride

1t/h

40% 1% φ0.8x10m Blast Furnace Slag

15t/h

6% 1% φ2x17m Bauxite Ore

8t/h

25% 3% φ1.5x12m Active Sludge

1.2t/h

85% 13% φ1.5x12m -

Your May Also Like

leave A Message

We will contact you as soon as possible