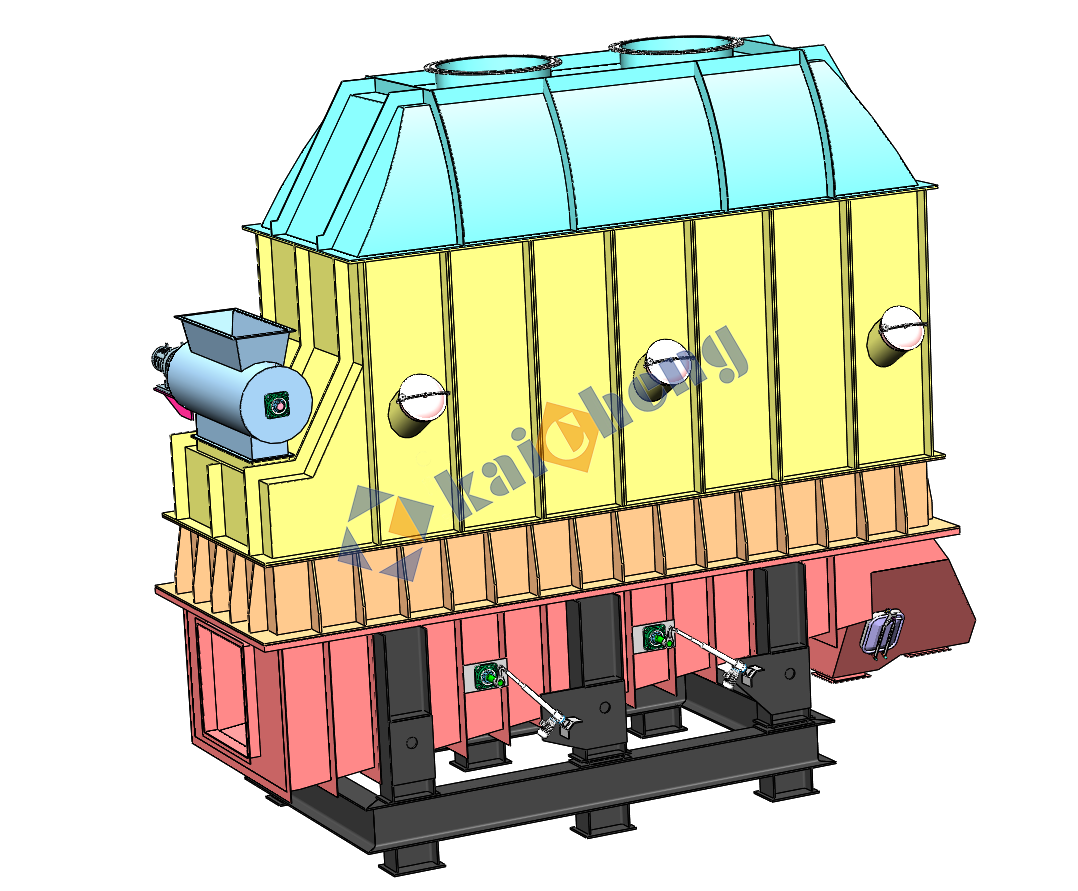

Large Three-channel Drum Dryer / Large Hot Air Dryer

The process principle of the large three-channel drum dryer is a heat drying process. As the dryer cylinder rotates, the internal scraper continuously scoops up the material, forming a material curtain, allowing the material to fully contact with the hot air. The multi-channel structure design more effectively utilizes heat and space, and the residence time of materials inside the dryer is longer than that of single-channel. The unique structural principle means that the product will not be over-dried or under-dried, and the product appearance will be good.

Product Attachments:

Keywords: Large Three-channel Drum Dryer / Large Hot Air Dryer

- Description

- Schematic Diagram

- Parameter

- Result

-

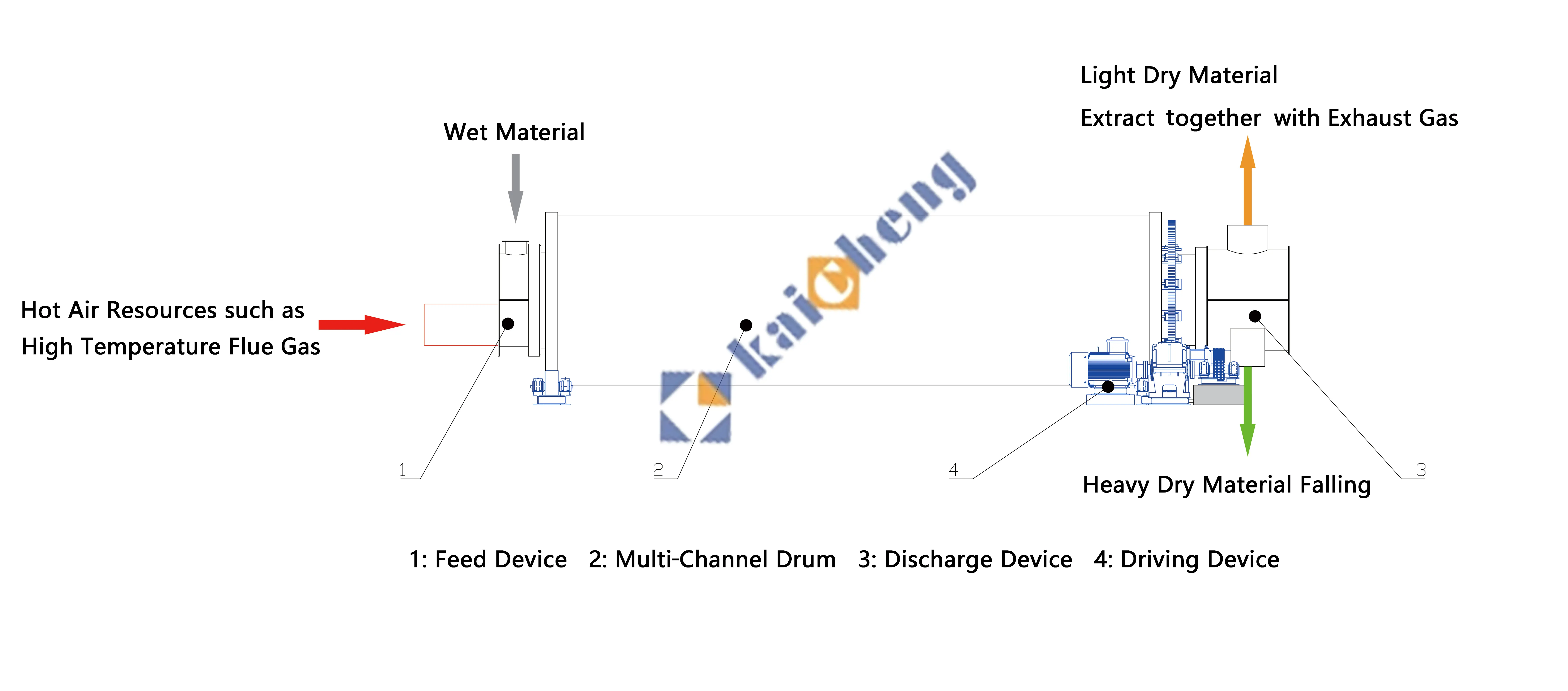

Working Principle:

The process principle of the large three-channel drum dryer is a heat drying process. As the dryer cylinder rotates, the internal scraper continuously scoops up the material, forming a material curtain, allowing the material to fully contact with the hot air.

The multi-channel structure design more effectively utilizes heat and space, and the residence time of materials inside the dryer is longer than that of single-channel.

The unique structural principle means that the product will not be over-dried or under-dried, and the product appearance will be good.

Equipment Characteristics:

- Large processing capacity: The maximum daily processing capacity of a single dryer is 500-720 t, and the evaporation capacity of a single machine is 15.5 t/h.

- Low energy consumption: tilizing waste high-temperature flue gas from cement plants, coal-fireo thermal power plants, and power plants as hot air resources, significantly reducing operating costs, making it one of the lowest energy consumption dryers in the world.

- High thermal efficiency: The material is in full contact with hot air, reducing heat loss, and the therma efficiency is as high as 73.6%.

- Low load of dust removal system: Unique feeding and discharging system and sealing system reduce material blockage and return.

- High Factor of safety of the equipment: the dryer is horizontally placed and supported by supporting rollers, which reduces mechanical wear and kinetic energy loss, operates stably and has low noise.

- Small floor area: this equipment occupies only one third of the floor area of similar single drum Rotary kiln equipment, and the civil construction cost and labor cost invested are greatly reduced.

- High product quality: The moisture content at the end of the material is stable, the product phase is uniform, and the calorific value is high.

- Applicable materials: Most powder and granular materials, especially for mineral drying in the mining industry, coal drying in the coal-to-hydrogen industry, and municipal sludge drying.

Adapt to Materials:

- Most of the powder granular materials

- Especially suitable for mineral drying in the mining industry

- Coal drying in the coal-to-hydrogen industry

- Municipal sludge drying

- Domestic waste industry: waste paper, waste furniture, waste silk, viscose blocks, waste pulp, fiberglass scraps, PE film, polyester film, mortar (a mixture of silica and resin, semi-solid), solid waste (fruit residue), waste packaging, waste textiles, and kitchen waste.

- Old waste: organic waste such as landfill waste, piled waste, mineralized waste or stock waste, food scraps, abandoned plants, livestock waste, etc.

Special note: Since the composition and shape of domestic waste and stale waste are diverse, and the dryer cannot enter large-volume integral materials, the harmless and resource-based treatment and reuse of domestic waste cannot be separated from the initial effective crushing tool.

Before drying, customers are required to crush it before drying. As shown in the figure below, the comparison before and after crushing

Development Trend:

At present, most of China's dryer market has been based on localization, with some government projects using imported equipment, but most of them are small dryers with a maximum daily processing capacity of 100 t.

The development trend of dryers in China in the future is large-scale, intensive, and resource-based, therefore there is an urgent need for large-scale dryers to fill the domestic market demand.

In order to save foreign exchange, it is of great practical significance to base on domestic research and development design and produce large three-channel drum dryers with a daily processing capacity of 500 t (including 80% moisture content material) to 720 t (60% moisture content material from plate and frame filter presses). -

-

Model Number

Evaporation Capacity

KC1800-10.5

1.05-2.34t/h

KC2750-9

2.13-3.78t/h

KC3200-9

3.08-5.62t/h

KC3350-12

3.92-7.16t/h

KC3810-12

5.62-10.34t/h

KC4000-20

8.61-15.10t/h

-

Your May Also Like

leave A Message

We will contact you as soon as possible