Feed Moisture Content:80%

Dryer/Sludge Dryer/Paddle Dryer/Powder Material Dryer/High Paste Material Dryer

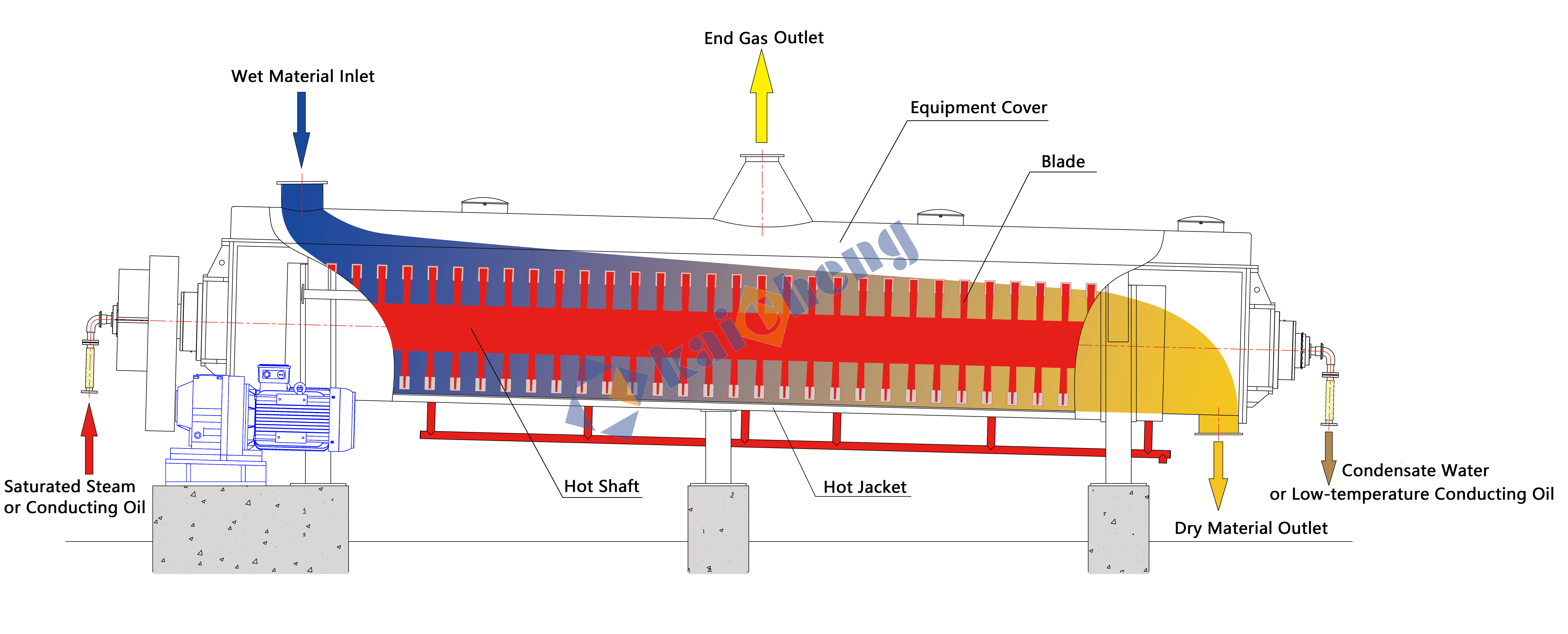

Bidirectional shear type sludge drying device with wedge-shaped blades is an indirect heating low-speed stirring dryer. There are two or four hollow rotating shafts inside the equipment, with wedge-shaped hollow blades densely arranged on the hollow shafts, and the thermal medium flows through the blades through the hollow shafts. The internal flow channel of the hot shaft is special and cleverly designed. The two shafts rotate in reverse, causing compression and relaxation between the shafts, constantly updating the heating surface of the material and greatly improving the evaporation efficiency.

Product Attachments:

Keywords: Dryer/Sludge Dryer/Paddle Dryer/Powder Material Dryer/High Paste Material Dryer

- Description

- Schematic Diagram

- Parameter

- Result

-

Working Principle:

Bidirectional shear type sludge drying device with wedge-shaped blades is an indirect heating low-speed stirring dryer.

There are two or four hollow rotating shafts inside the equipment, with wedge-shaped hollow blades densely arranged on the hollow shafts, and the thermal medium flows through the blades through the hollow shafts.

The internal flow channel of the hot shaft is special and cleverly designed. The two shafts rotate in reverse, causing compression and relaxation between the shafts, constantly updating the heating surface of the material and greatly improving the evaporation efficiency.

Common thermal media include steam, heat transfer oil, hot water and cooling water, which can complete unit operation such as drying, cooling, heating and reaction.

Equipment Characteristics:

- Achievements in "Localization" major equipment science and technology research, national patent Products

- Using steam as the heat transfer medium, it can be used for both semi drying and full drying, with a simple system and fewer auxiliary equipment

- Steam does not come into contact with materials, and the amount of non condensable gas in the tail gas is low. lt can be directly burned in the furnace, resulting in low secondary pollution

- Fully sealed negative pressure operation, with minimal dust in the workshop and minima environmental pollution

- Strong adaptability to sludge moisture content, able to adapt to sludge with moisture content of 60%-90%

- The thermal efficiency can reach 90%, the evaporation intensity is high, the energy consumption is low and the operating cost is low

- Large single machine processing capacity, maximum processing capacity: 180 t/d

- Single machine with large heat transfer area, compact structure, and small footprint

- High reliability, low maintenance volume, and can operate continuously day and night

Adapt to Materials:

- Sludge: municipal sludge, printing and dyeing sludge, leather sludge, paper sludge, electroplating sludge, etc.

- Chemical industry: soda ash, activated carbon, calcium carbonate, silica, titanium dioxide, barium sulfate, molecular sieve, kaolin, EDTA, etc.

- Plastics industry: polypropylene, polyethylene, polyvinyl chloride, ABS, etc.

- Food and feed industry: condiments, distiller's grains, sauce residue, vinegar residue, fish meal, soybean meal, etc.

-

- Wholly drying of sludge: The incoming sludge has a moisture content of 60%-90% (wet basis), and the moisture content at the end after drying is 10% (wet basis).

- Semi-drying of sludge: The incoming sludge has a moisture content of 60%-90% (wet basis), and the moisture content at the end after drying is <40% (wet basis).

- Exhaust gas: The exhaust gas generated during the drying process is sent to the exhaust main through the exhaust gas treatment system, with a fully enclosed negative pressure operation to prevent odor emissions.

- Condensate water: Condensate water is collected and transported to the boiler soft water tank for recycling, and is reused as a resource.

- Sewage: Sewage is collected and transported to the sewage treatment system, without causing environmental pollution.

-

Equipment Model Heat Transfer Area Evaporation Capacity SZ-25

25㎡

200-300kg/h

SZ-30

30㎡

240-360kg/h

SZ-45

45㎡

360-540kg/h

SZ-65

65㎡

520-780kg/h

SZ-82.5

82.5㎡

660-990kg/h

SZ-110

110㎡

880-1320kg/h

SZ-130 130㎡ 1000-1350kg/h SZ-150

150㎡

1200-1800kg/h

SZ-180

180㎡

1440-2160kg/h

SZ4-220

220㎡

1760-2640kg/h

SZ4-253

253㎡

2024-3036kg/h

SZ4-280

280㎡

2240-3360kg/h

SZ4-360

360㎡

2880-4320kg/h

SZ4-400

400㎡

3200-4800kg/h

SZ4-468

468㎡

3744-5616kg/h

SZ4-500

500㎡

4000-6000kg/h

-

Previous: none

Your May Also Like

leave A Message

We will contact you as soon as possible