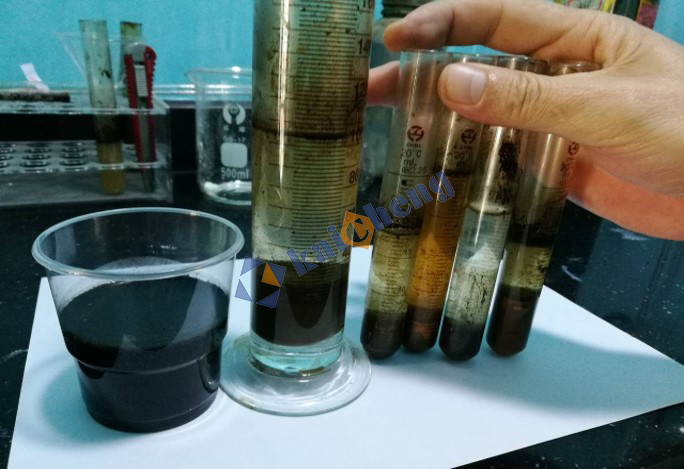

Separation After Adding Chemicals

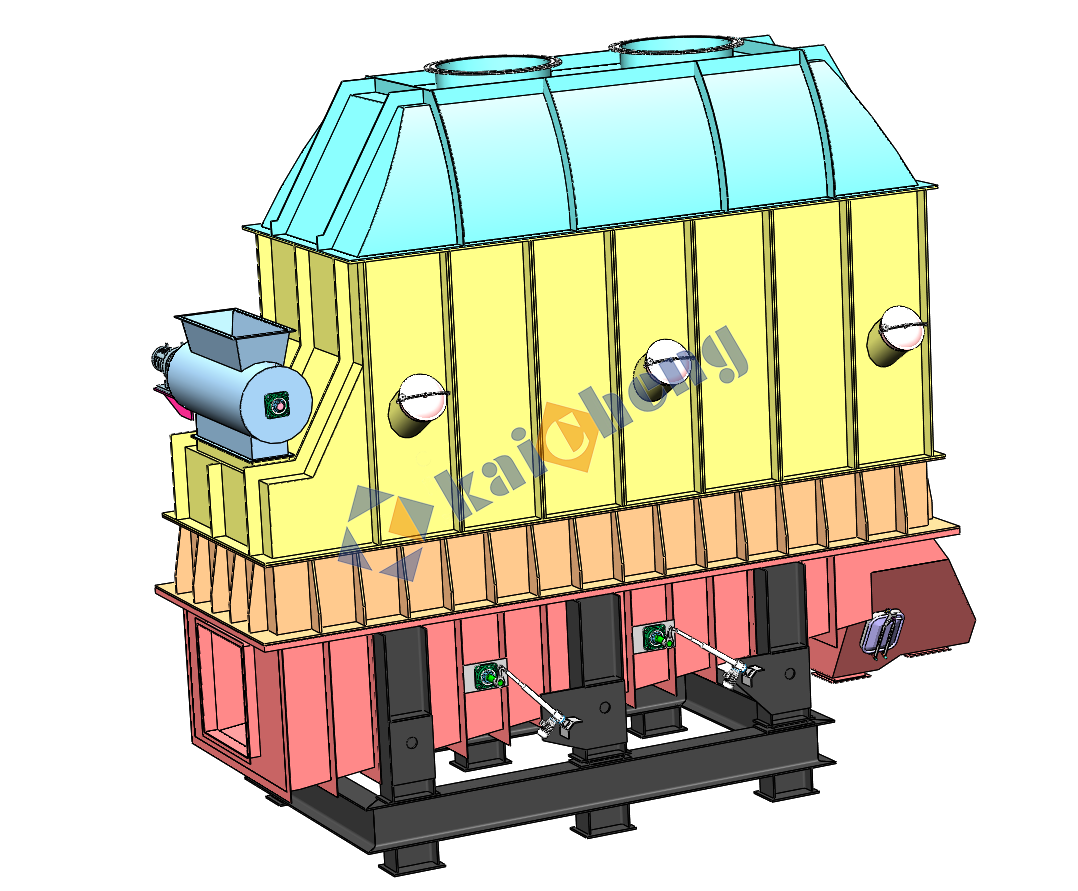

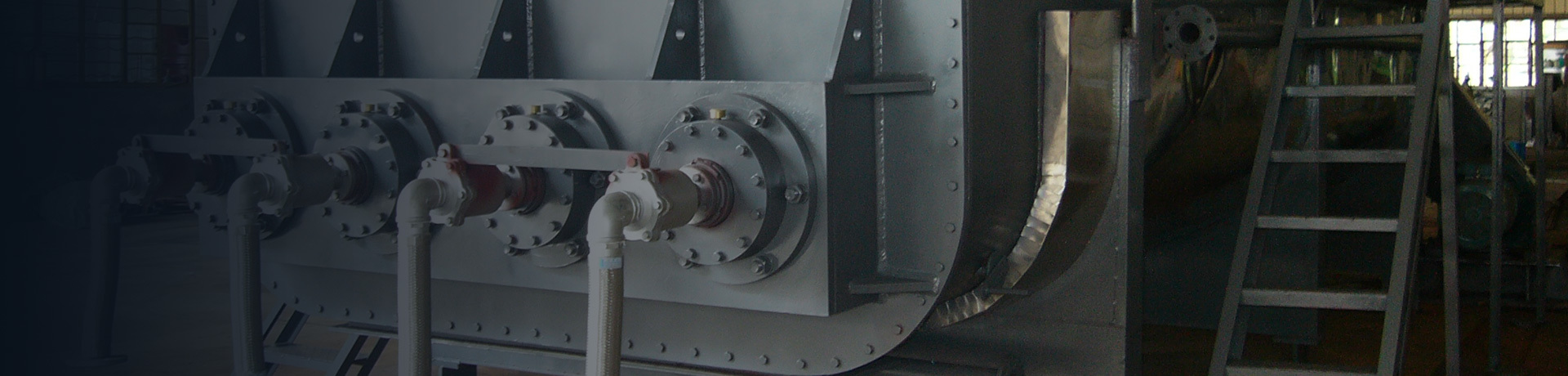

Drying of Oily Sludge

Acid precipitation process: Adopt chemical acid precipitation + oil-bearing sludge drying method to remove oil. The core of the process technology is to break the "water-in-oil" emulsified molecular bonds in the oil sludge or oil slurry through chemical reactions, achieving oil-water separation, which naturally separates inorganic matter.Through three-phase separation, some recovered oil is finally formed. The generated inorganic sediment (a small amount of oil-bearing or trace oil-bearing) is dried with oil-bearing sludge.

Product Attachments:

Keywords: Drying of Oily Sludge

- Description

- Schematic Diagram

- Parameter

- Result

-

Definition Of Oily Sludge:

1. "Three types of sludge" in refineries: oil separator dross, tank bottom sludge, and biochemical sludge.

2. Oil sludge soil and drilling oil sludge contaminated during the process of drilling and extracting oil.

3. Riverbed sediment and silt contaminated during the discharge of oily sewage.Characteristics of Oily Sludge:

- Characteristics of asphalt-based

- Characteristics of paraffin base

- High oil content

- Macromolecular chains

- High viscosity

- High Thixotropy

- Cannot be molded

- High storage and transportation costs

Acid Precipitation Process:

Acid precipitation process: Adopt chemical acid precipitation + oil-bearing sludge drying method to remove oil.

The core of the process technology is to break the "water-in-oil" emulsified molecular bonds in the oil sludge or oil slurry through chemical reactions, achieving oil-water separation, which naturally separates inorganic matter.Through three-phase separation, some recovered oil is finally formed.

The generated inorganic sediment (a small amount of oil-bearing or trace oil-bearing) is dried with oil-bearing sludge.Oil Sludge Drying:

Oily sludge after oil removal by chemicals (oil content: 4%-5.23%).

It is transported to the complete set of equipment for drying oily sludge through a screw conveyor.Sinopec Jiujiang Company Project:

-

-

-

The dried oily sludge is in powder form, with a moisture content of about 20% and a calorific value of 3200kcal/kg.

Feed Moisture Content:85%,End Moisture Content:20%,The reduction reached 81.25%.

Previous: Horizontal Disc Dryer

Next: Pyrolysis of Oily Sludge

Your May Also Like

leave A Message

We will contact you as soon as possible