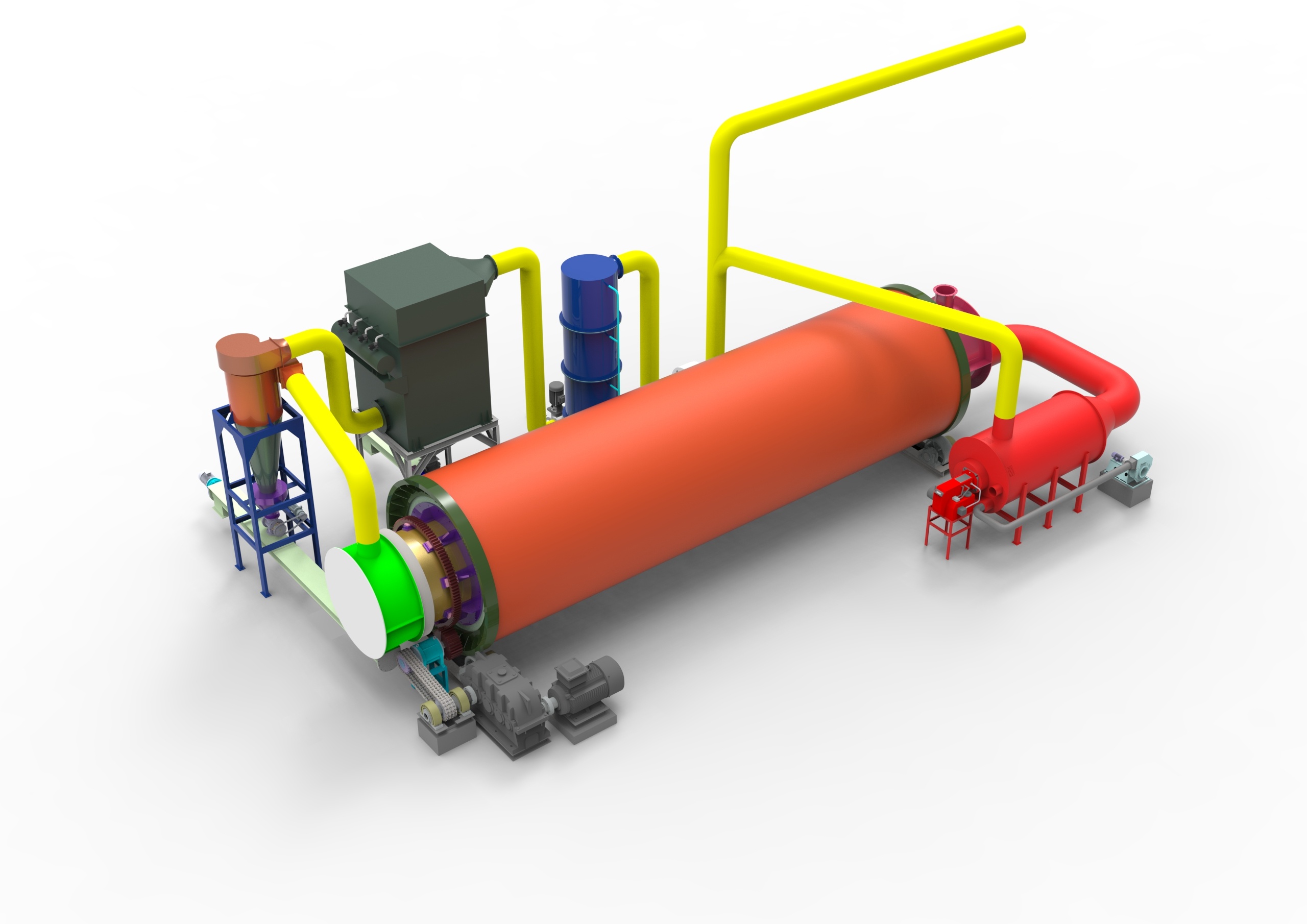

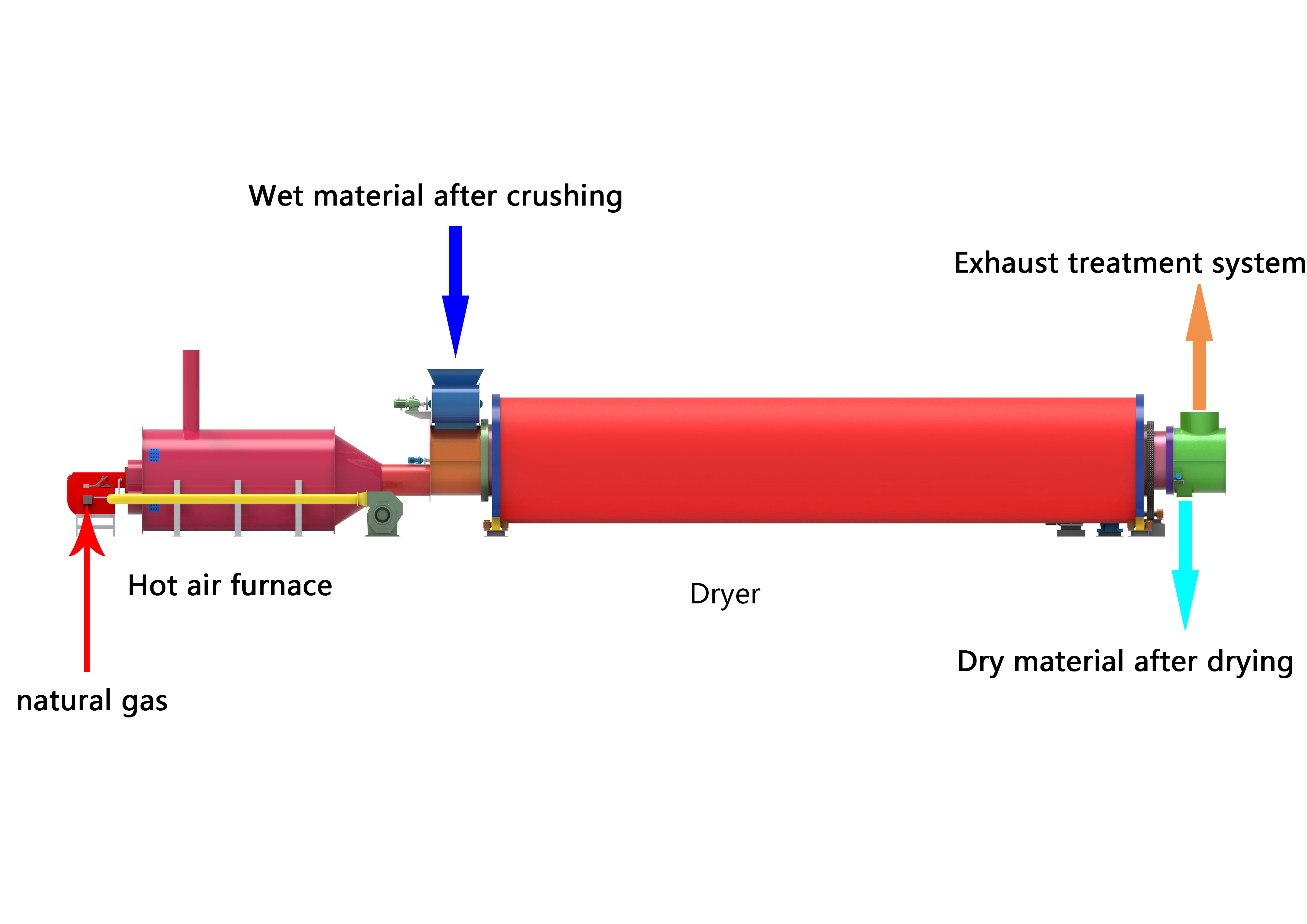

Slime Dryer / Mineral Powder Dryer / Mineral Dryer

To process these large amounts of mineral powder, minerals, and sludge, a large dryer is needed for drying. We provide dryers with a maximum processing capacity of 500-720t/d for customers to choose.

Product Attachments:

Keywords: Slime Dryer / Mineral Powder Dryer / Mineral Dryer

- Description

- Schematic Diagram

- Parameter

- Result

-

Design Background

Tailing waste generated in water-based ore dressing or washing operations is often discharged in the form of slurry. After sedimentation, the wastewater is reused and the sediment is called ore mud.

According to its source, ore mud can be divided into two types: the ore mud generated in the process of grinding and crushing ore is called secondary ore mud; the ore mud generated in the ore deposit due to geological action is called primary ore mud. The more ore mud, the greater the harmful effect on flotation. The most fundamental way is to prevent the generation of secondary ore mud as much as possible.

The tailings volume of ferrous metal ores is more than 90%; the water-based tailings of uranium ore are more than 99.9-99.99%. Tailings are generally discharged from the ore dressing plant in the form of slurry, and their particle size is generally 0.001-1mm. Sometimes the content of particles below 0.074mm is as high as 85%. After drying, they fly with the wind and pollute the atmosphere. Usually, the main treatment method for tailings is to build tailings dams or store them in tailings ponds. Although the comprehensive utilization of tailings waste has developed, there are still many problems to be solved.Equipment Selection

To process these large amounts of mineral powder, minerals, and sludge, a large dryer is needed for drying.

We provide dryers with a maximum processing capacity of 500-720t/d for customers to choose.

-

-

型号规格

Model Specifications

直径

Diameter

长度

Length

蒸发量

Evaporation

KC1.8-10.5

φ1800mm

10500mm

1.07-1.87t/h

KC2.74-9

φ2740mm

9000mm

2.13-3.78/th

KC3.2-9

φ3200mm

9000mm

3.08-5.62/th

KC3.35-12

φ3350mm

12000mm

3.92-7.16/th

KC3.81-12

φ3810mm

12000mm

5.62-10.34/th

KC3.96-18

φ3960mm

18000mm

8.61-15.10/th

KC4-20

φ4000mm

20000mm

10.05-17.58/th

-

After drying, the moisture content of the sludge/mineral powder/mineral can reach below 10%.

Your May Also Like

leave A Message

We will contact you as soon as possible