PRODUCTS

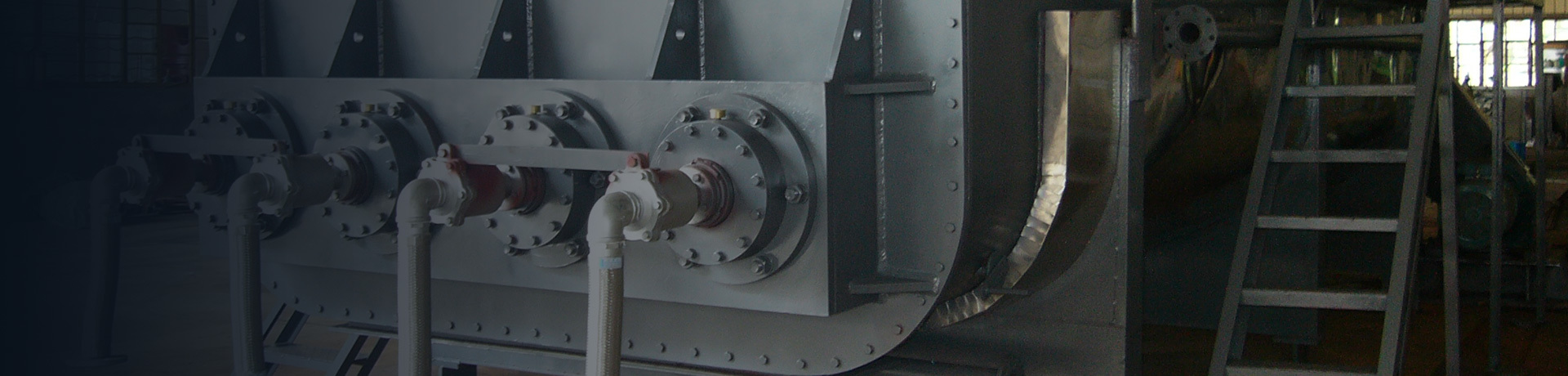

At present, the company has launched a disc dryer with a maximum heat transfer area of 518 square meters,Contains tungsten carbide spraying, wear and corrosion resistance, suitable for drying highly abrasive materialsThe material is fed into the dryer through the feed port. The working medium flows between the shell and the hollow shaft. Heat is transmitted through the jacket, the hollow shaft and the hollow disc welded on the shaft. The material is indirectly heated and dried, and the generated water vapor gathers. In the dome of the dryer, the carrier gas is carried out of the dryer. The hollow disc is perpendicular to the shaft and does not cut the material. Through the action of the propeller/agitator on the edge of the disc, the material is pushed and stirred, and the drying surface is constantly updated, thereby achieving the purpose of drying.

Learn More